pipewelder1999

Industrial

- Mar 17, 2002

- 309

The question here is related to a discussion I have had and observed many times over the years.

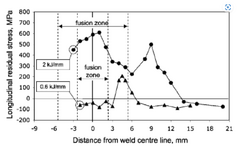

I'm not interested in what codes/specifications say or do not say, I'm interested in research that shows the results of the "Welds too close" topic that has been addressed here, on jobs, and other places online.

I read through one paper at https://www.researchgate.net/public...uctures_Pipelines_And_Piping_State_Of_The_Art that have me some other references but as someone who is NOT an engineer, this will take some digesting.

I am looking for something definitive that contrasts the difference in mechanical properties resulting from the welds being "too close". I am continuing to look and learn but any information is appreciated that can lead me to the "why and when" separation of welds by a specific distance should be a consideration.

As an inspector, I don't make engineering decisions but this topic has come up many times.

Thanks.

Gerald Austin

Greeneville TN

I'm not interested in what codes/specifications say or do not say, I'm interested in research that shows the results of the "Welds too close" topic that has been addressed here, on jobs, and other places online.

I read through one paper at https://www.researchgate.net/public...uctures_Pipelines_And_Piping_State_Of_The_Art that have me some other references but as someone who is NOT an engineer, this will take some digesting.

I am looking for something definitive that contrasts the difference in mechanical properties resulting from the welds being "too close". I am continuing to look and learn but any information is appreciated that can lead me to the "why and when" separation of welds by a specific distance should be a consideration.

As an inspector, I don't make engineering decisions but this topic has come up many times.

Thanks.

Gerald Austin

Greeneville TN