MyCupboard

Structural

- Aug 23, 2022

- 27

I have been in residential structural engineering for about 8 years. I know there are some things that are a “big deal” and other things that can SOMETIMES be approved simply because of redundancy and oversimplification of the system.

Tied roof concepts tend to be a good topic with varying opinions. This specific question is related to when roof rafters (sloped) and ceiling joists (flat) meet at a flush bottom beam.

In typical wall details for the house, the rafter laps the ceiling joist and is fastened accordingly to resist the thrust. So where they come together at a flush beam I just thought they would align the beam appropriately so that they overlapped, get fastened, and both hang off the beam.

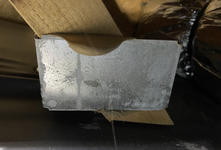

During a frame walk today, I came across this little detail. I’m curious to hear everyone’s thoughts. Mine range from (there is still a bunch of nails scattered into the lapped portion), to (should I have called out separate hangers because of the sloped condition and flat condition?), or (couldn’t they have located the beam so that there was more of a “seat” at the bottom of the roof rafter that could then hang into the beam with the double hanger?

I am by no means an all knowing expert, but considering this builder is extremely confident and proving to be not at all competent, I’d like to get some wisdom before I address this line item.

For clarification, they scabbed an angled member to the side of the ceiling joist to create a flush bearing condition at the hanger. That’s my guess at least.

Tied roof concepts tend to be a good topic with varying opinions. This specific question is related to when roof rafters (sloped) and ceiling joists (flat) meet at a flush bottom beam.

In typical wall details for the house, the rafter laps the ceiling joist and is fastened accordingly to resist the thrust. So where they come together at a flush beam I just thought they would align the beam appropriately so that they overlapped, get fastened, and both hang off the beam.

During a frame walk today, I came across this little detail. I’m curious to hear everyone’s thoughts. Mine range from (there is still a bunch of nails scattered into the lapped portion), to (should I have called out separate hangers because of the sloped condition and flat condition?), or (couldn’t they have located the beam so that there was more of a “seat” at the bottom of the roof rafter that could then hang into the beam with the double hanger?

I am by no means an all knowing expert, but considering this builder is extremely confident and proving to be not at all competent, I’d like to get some wisdom before I address this line item.

For clarification, they scabbed an angled member to the side of the ceiling joist to create a flush bearing condition at the hanger. That’s my guess at least.