Eng_Struct

Structural

Hi Group,

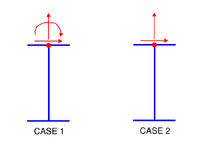

I need to provide guy wire anchors to support the mechanical duct for wind uplift. The wires will be installed at roughly 45-60 degree angle and the guy wire anchor will consist of a round HSS tube with eye-bolt and base plate that will be welded to the roof beam top flange.

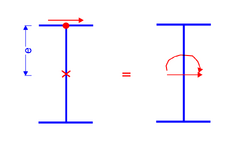

There is no access from below to install any additional members to take the torsion out. I wanted to confirm if the anchor is placed close to the joist shoe, is there a way for me to resolve the moment into axial force into the joist?

I have tried resolving the moment into horizontal tensions and compression force at the top and bottom flange - the top flange will be OK as it is restrained by the joists however there is nothing restraining the bottom chord for the entire span length and the horizontal force from the anchor moment will reuslt in a huge moment in the bottom flange bending in laterally.

Any suggestions or ideas will be helpfull. I have attached a sketch to explan the condition.

Thanks in Advance!

I need to provide guy wire anchors to support the mechanical duct for wind uplift. The wires will be installed at roughly 45-60 degree angle and the guy wire anchor will consist of a round HSS tube with eye-bolt and base plate that will be welded to the roof beam top flange.

There is no access from below to install any additional members to take the torsion out. I wanted to confirm if the anchor is placed close to the joist shoe, is there a way for me to resolve the moment into axial force into the joist?

I have tried resolving the moment into horizontal tensions and compression force at the top and bottom flange - the top flange will be OK as it is restrained by the joists however there is nothing restraining the bottom chord for the entire span length and the horizontal force from the anchor moment will reuslt in a huge moment in the bottom flange bending in laterally.

Any suggestions or ideas will be helpfull. I have attached a sketch to explan the condition.

Thanks in Advance!