Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

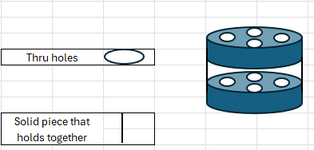

"There is unlikely to be a Fanuc instruction that says "Make random holes incorrectly."The simple answer is that conditions for drilling two of the hole pairs are not the same as for drilling the other two hole pairs.

It could be a lubricant flow difference, a different drill cycle, some asymmetrical deflection in the part or a fixture.

There is unlikely to be a Fanuc instruction that says "Make random holes incorrectly."