Hello All,

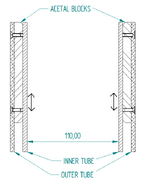

I am working on a telescopic column. The design is two square Aluminium tubes supported by internal Acetal wear blocks. There is a payload on the inner tube and it is driven up and down, the external tube is static.

I am frequently getting a 9 Hz vibration mode occurring as I drive the inner column down. As the vibration occurs at all speeds, positions and with different drives, I have managed to rule out all of the geartrain mechanics (belts, gears, leadscrew etc) and any motor interference. I also made another version with roller bearings instead of blocks and there were no vibrations, this design was not feasible for other reasons however. Different materials with better sliding properties have also been tried for the blocks.

I am confident in saying the vibration is caused by the friction forces and interaction between the tubes and the blocks.

However, I am at a loss as to precisely how or where the 9 Hz is originates. Any calcs I try give resonances many orders of magnitude higher than this. I would really appreciate some pointers or advice.

Other information

- The vibration only occurs when the payload is driven down (with gravity).

- The vibration only occurs near max payload.

- The vibration can be worse if the payload is offset, probably causing an out-of-plane twist to the inner column.

- The vibration is only in the y axis (as looking at the image below)

- There is also a 92 Hz vibration mode, I am unsure whether it is connected, but I am less worried about this for now.

All help is much appreciated

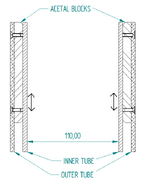

I am working on a telescopic column. The design is two square Aluminium tubes supported by internal Acetal wear blocks. There is a payload on the inner tube and it is driven up and down, the external tube is static.

I am frequently getting a 9 Hz vibration mode occurring as I drive the inner column down. As the vibration occurs at all speeds, positions and with different drives, I have managed to rule out all of the geartrain mechanics (belts, gears, leadscrew etc) and any motor interference. I also made another version with roller bearings instead of blocks and there were no vibrations, this design was not feasible for other reasons however. Different materials with better sliding properties have also been tried for the blocks.

I am confident in saying the vibration is caused by the friction forces and interaction between the tubes and the blocks.

However, I am at a loss as to precisely how or where the 9 Hz is originates. Any calcs I try give resonances many orders of magnitude higher than this. I would really appreciate some pointers or advice.

Other information

- The vibration only occurs when the payload is driven down (with gravity).

- The vibration only occurs near max payload.

- The vibration can be worse if the payload is offset, probably causing an out-of-plane twist to the inner column.

- The vibration is only in the y axis (as looking at the image below)

- There is also a 92 Hz vibration mode, I am unsure whether it is connected, but I am less worried about this for now.

All help is much appreciated