We have an OLD CH motor controller on a Tocco motor-generator for induction furnace. Nameplate shows: 500HP 60Hz 440V 520A 3ph.

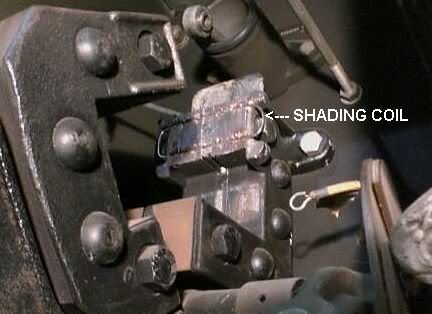

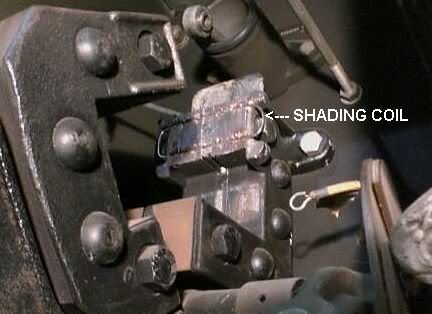

From time to time, the shading coil on one of the contactors burns out. We have some spare coils on hand, and also have some "new" ones that were made in house a few years ago. Yesterday when one failed (which is how I became involved in the issue), we replaced the failed coil with one of the "new" in-house produced coils. It appeared to be nickel-plated copper wire, and was very ductile. After installing and switching the motor-generator on, one section of the shading coil began to glow cherry red. We immediately shut down, and replaced it with one of the older ones, and the problem went away.

The older ones are much stiffer (not easily bent like the "new" ones), and have a copper color. One of the techs here said that many years ago he called the Cutler Hammer service folks and they said we could make replacement shading coils out of brazing wire.

So finally to the question: What material should shading coils be made of?

From time to time, the shading coil on one of the contactors burns out. We have some spare coils on hand, and also have some "new" ones that were made in house a few years ago. Yesterday when one failed (which is how I became involved in the issue), we replaced the failed coil with one of the "new" in-house produced coils. It appeared to be nickel-plated copper wire, and was very ductile. After installing and switching the motor-generator on, one section of the shading coil began to glow cherry red. We immediately shut down, and replaced it with one of the older ones, and the problem went away.

The older ones are much stiffer (not easily bent like the "new" ones), and have a copper color. One of the techs here said that many years ago he called the Cutler Hammer service folks and they said we could make replacement shading coils out of brazing wire.

So finally to the question: What material should shading coils be made of?