PhD researcher here (background in biological sciences, but taking PhD in civil engineering).

TLDR: Does anyone know where to source suitable sand for slow sand filtration (e.g., imports from Portugal)? Also, how is filtration rate mostly controlled in slow sand filters—via the outlet valve or resistance to flow from small porosity?

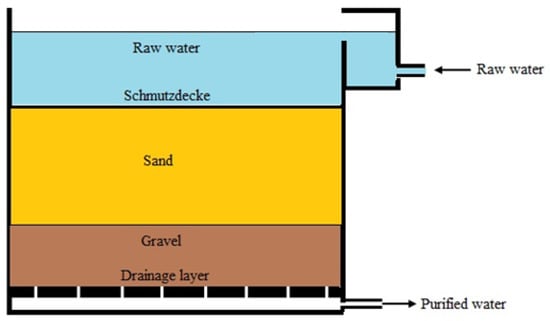

Our project is on slow sand filtration and the removal of pharmaceuticals but we are running into problems manufacturing a large-scale testing column.

Initial research confirmed that an effective size (D10) smaller than 0.25 mm is ideal (slowing filtration rate = increased filter efficiency), but smaller again is ideal. It is proving difficult to find such a sand as most stone suppliers local to us (Ireland) cannot provide a sand with a small enough particle size. The sand we are recieving from them typically ends up around 0.30 mm (despite being labelled as smaller than this, and for sand filtration). Chatting to the director of sales from one of these quarries, he said that their company was the supplier to most water treatment companies in the north and south of Ireland so we thought we were on the money. However, lab testing shows the permeability and flow rate through these sands is much too fast (nowhere near the 0.2 - 0.4 m/h recommended). My suspicion is that these sands are being purchased for pressure and rapid gravity filters, not *slow* sand filters. My first question is this - if you are a slow sand filter designer/operator/etc., where do you source your sand from? We had rumours of sand being imported from Portugal.

My second question is this, most studies on slow sand filtration do not report physically how they controlled the filtration rate, so how is this done? Is this by a control valve at the outlet? I feel like this is too simple and totally negates the principle of treatment by the water percolating through the sand under gravity. Yes, the smaller the pore size means pores between grains are smaller and therefore there is more resistance to the flow of water thus a slower filtration rate. But one test of sand with a D10 of 0.15 mm was still flowing much too quickly (0.7 m/h).

TLDR: Does anyone know where to source suitable sand for slow sand filtration (e.g., imports from Portugal)? Also, how is filtration rate mostly controlled in slow sand filters—via the outlet valve or resistance to flow from small porosity?

Our project is on slow sand filtration and the removal of pharmaceuticals but we are running into problems manufacturing a large-scale testing column.

Initial research confirmed that an effective size (D10) smaller than 0.25 mm is ideal (slowing filtration rate = increased filter efficiency), but smaller again is ideal. It is proving difficult to find such a sand as most stone suppliers local to us (Ireland) cannot provide a sand with a small enough particle size. The sand we are recieving from them typically ends up around 0.30 mm (despite being labelled as smaller than this, and for sand filtration). Chatting to the director of sales from one of these quarries, he said that their company was the supplier to most water treatment companies in the north and south of Ireland so we thought we were on the money. However, lab testing shows the permeability and flow rate through these sands is much too fast (nowhere near the 0.2 - 0.4 m/h recommended). My suspicion is that these sands are being purchased for pressure and rapid gravity filters, not *slow* sand filters. My first question is this - if you are a slow sand filter designer/operator/etc., where do you source your sand from? We had rumours of sand being imported from Portugal.

My second question is this, most studies on slow sand filtration do not report physically how they controlled the filtration rate, so how is this done? Is this by a control valve at the outlet? I feel like this is too simple and totally negates the principle of treatment by the water percolating through the sand under gravity. Yes, the smaller the pore size means pores between grains are smaller and therefore there is more resistance to the flow of water thus a slower filtration rate. But one test of sand with a D10 of 0.15 mm was still flowing much too quickly (0.7 m/h).