trucksmart

Automotive

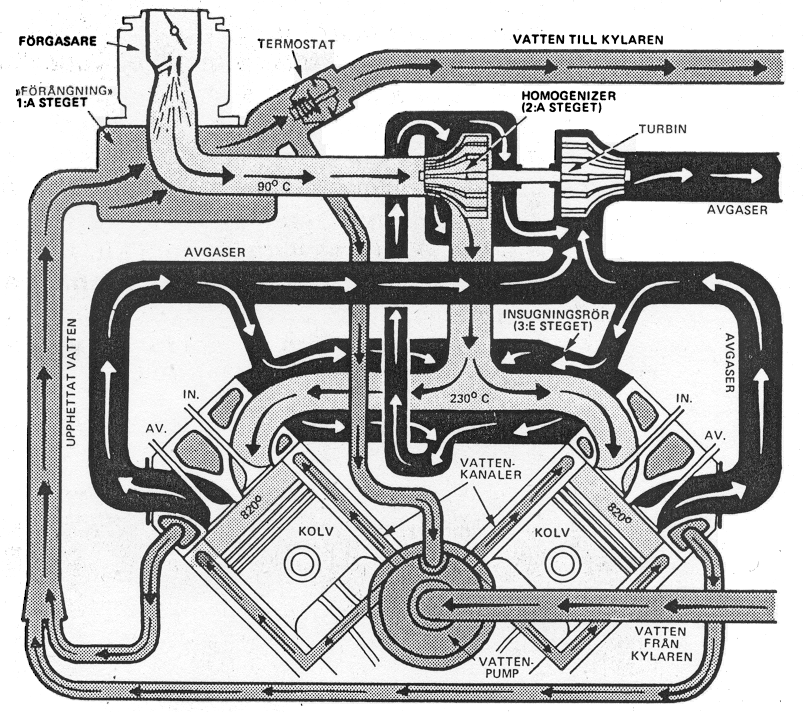

I think after reading the threads about Smokey's VW Rabbit 2 cylinder high mileage engine, everyone seems to be missing the main process that makes the engine so efficient. I thought the engine used two turbo chargers when I read about it in the 1970's. The whole idea was to homogenize the fuel air mixture so the lighter ends of the carbon were mixed up with all the other fractions of carbon and because it was so hot and moving under pressure it didn't have time to separate and ignite before the rest of the mixture burned. It was just a nice controlled continuous burn similar to that of a diesel engine combustion. This is why the engine never pinged or knocked even when starting from a dead start and slamming the throttle to the floor. That was the secret everyone is asking for.

I believe the fuel/air mixture went through two turbos before going into the combustion chambers. Because the mixture was completely homogenized and it was under high boost pressure it couldn't pre-ignite. The whole intake system was plastered with asbestos insulation so very little of the heat energy escaped from going out the tail pipe. You could probably hold your hand on the surface of the insulation without burning your hand. Look at how much money Mercedes Benz spent on their steam recovery hybrid (which never made it to production) and Smokey did it better and for very little money. (he actually stuffed a potato up tail pipes to diagnose the health of engines. He had and used common sense while it was still common.

The only problem to me seemed to be that it wasn't very quick off the starting line and they couldn't seem to find a way to file the patent but was had very smooth acceleration. What was amazing was he achieved 150 horse power from a two cylinder engine. Just think what he could have achieved from a heavy duty truck V-8 engine with this technology? Remember; with the homogenized vapor at several hundred degrees F. the molecules aren't very close together so it would take a lot of boost to fuel the engine at high power demands.

I think Smokey Yunick was just trying to prove a point and that is to find a way to more completely burn the fuel making the engine more efficient. I think he succeeded.

I believe the fuel/air mixture went through two turbos before going into the combustion chambers. Because the mixture was completely homogenized and it was under high boost pressure it couldn't pre-ignite. The whole intake system was plastered with asbestos insulation so very little of the heat energy escaped from going out the tail pipe. You could probably hold your hand on the surface of the insulation without burning your hand. Look at how much money Mercedes Benz spent on their steam recovery hybrid (which never made it to production) and Smokey did it better and for very little money. (he actually stuffed a potato up tail pipes to diagnose the health of engines. He had and used common sense while it was still common.

The only problem to me seemed to be that it wasn't very quick off the starting line and they couldn't seem to find a way to file the patent but was had very smooth acceleration. What was amazing was he achieved 150 horse power from a two cylinder engine. Just think what he could have achieved from a heavy duty truck V-8 engine with this technology? Remember; with the homogenized vapor at several hundred degrees F. the molecules aren't very close together so it would take a lot of boost to fuel the engine at high power demands.

I think Smokey Yunick was just trying to prove a point and that is to find a way to more completely burn the fuel making the engine more efficient. I think he succeeded.