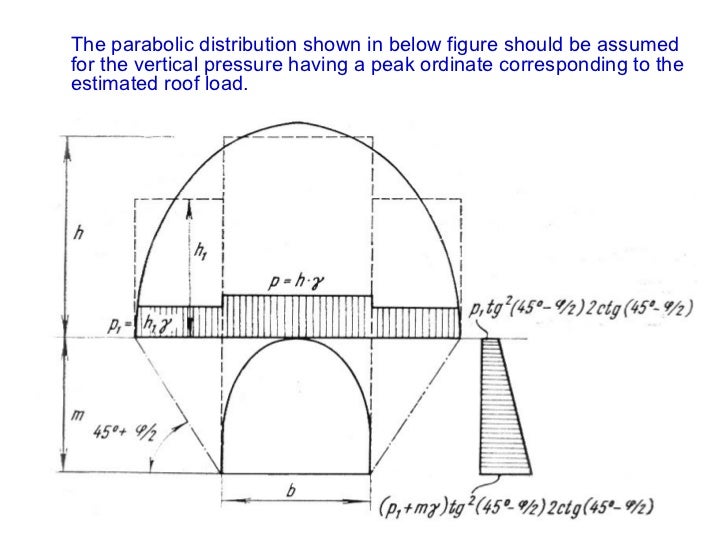

I'm designing the footings for precast tunnel shells. The tunnel is located 20m below grade and the footings are concentrically placed to the tunnel shell walls so as to avoid any instability.

Would it be correct to assume the soil column over the overhanging part of the footing can be ignored due to arching effects in the soil?

In my case, this is the difference between a simple strip footing and an expensive thick mat footing.

0 to 10m is loose fill material

10m to 20m is natural stiff clay overlying weathered rock (weathered rock layer about 3m below tunnel footings).

Would it be correct to assume the soil column over the overhanging part of the footing can be ignored due to arching effects in the soil?

In my case, this is the difference between a simple strip footing and an expensive thick mat footing.

0 to 10m is loose fill material

10m to 20m is natural stiff clay overlying weathered rock (weathered rock layer about 3m below tunnel footings).