TMcRally

Automotive

- Aug 17, 2007

- 155

Hi, I moved this post as I had parked it in the wrong place.... Sorry

Could people smarter than me fact check or advise where I'm right and where I'm wrong. TIA

I have a need to produce a small run of permanent magnet, Latching solenoid that have =/>15N @12mm - More is better....

I have 24Vdc @ 3Amps,

Size is restricted to 68mm x 31mm x 30mm - I have no additional space for a capacitor and second coil.

Through my own research and help along the way I have come up with this, I have no idea if it will produce the pull force I need.

In use it will have a 300ms pulse to retract and a reversed polarity pulse to release.

Duty cycle will be less than 5%.

What I think I know but could easily be wrong...

What I definitely don't know....

Could people smarter than me fact check or advise where I'm right and where I'm wrong. TIA

I have a need to produce a small run of permanent magnet, Latching solenoid that have =/>15N @12mm - More is better....

I have 24Vdc @ 3Amps,

Size is restricted to 68mm x 31mm x 30mm - I have no additional space for a capacitor and second coil.

Through my own research and help along the way I have come up with this, I have no idea if it will produce the pull force I need.

In use it will have a 300ms pulse to retract and a reversed polarity pulse to release.

Duty cycle will be less than 5%.

What I think I know but could easily be wrong...

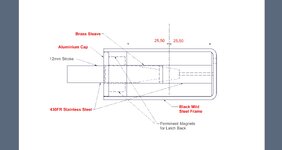

- 90m of 0.5mm winding for approximately 1,500 coils

- 10.3mm dia armature

- 430FR Stainless steel armature and core - I have seen a few options on this, I'm happy to change if it sees an improvement in pull force.

- Mild steel frame

- Aluminum end cap

- 2x Neodymium bar magnets

- Plastic Magnet holder

- 11.2mm OD x 10,4mm ID Brass sleave

What I definitely don't know....

- should the brass sleeve extend over the core or as I've drawn it to shield the winding from the moving armature with a 2mm overlap for alignment with the core.

- should the armature overlap the core when retracted with the centerline of the overlap aligned to the centerline of the coil

- does it matter how much ferrous material extends out of the solenoid or should any attachments be non-ferrous

- should the tapper on the armature be inside the cone when extended or is flush optimum

- optimum ramp angle of the taper on the cone and armature

- minimum x section of the end of the taper