Hello,

This is my first thread, nice to meet you all.

I am a freshly graduated environmental engineer and I started working as a process engineer in the wastewater treatment area and I need some recommendations or ideas for a project that I am working on.

In the project we are working with wastewater from a dairy production. There are two parallel mixing and equalization tanks and two parallel spill basins. They are all going to be build underground. The spill basins will be filled with the floating sludge from the MAB through an overflow pipe (not in the 3D design yet) or in case of an emergency/spill, the wastewater directly will go to the spill basins.

There will not be an aeration in the spill basin and it is highly possible there is going to be a biogenic sulfuric acid corrosion on the concerete tank. That is why the senior engineers decided to go with a HDPE cover in all the tank. Then they tasked me to find out possible problems and what I offer to solve them. I already made some progress with some points but there are couple of things that I couldn't figure out yet and I need your help.

Edit: I wrote we need an agitator but we don't have that intention anymore. Therefore, Point 3 is edited.

This is my first thread, nice to meet you all.

I am a freshly graduated environmental engineer and I started working as a process engineer in the wastewater treatment area and I need some recommendations or ideas for a project that I am working on.

In the project we are working with wastewater from a dairy production. There are two parallel mixing and equalization tanks and two parallel spill basins. They are all going to be build underground. The spill basins will be filled with the floating sludge from the MAB through an overflow pipe (not in the 3D design yet) or in case of an emergency/spill, the wastewater directly will go to the spill basins.

There will not be an aeration in the spill basin and it is highly possible there is going to be a biogenic sulfuric acid corrosion on the concerete tank. That is why the senior engineers decided to go with a HDPE cover in all the tank. Then they tasked me to find out possible problems and what I offer to solve them. I already made some progress with some points but there are couple of things that I couldn't figure out yet and I need your help.

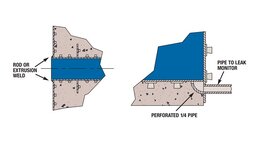

- Firstly, in case of a spill, the basin will be filled with the pipes from a high point and the water will have a certain impact on one point continuosly which is covered with HDPE. Would that be a problem in the long term?

- I would like to place a ladder in front of the plates that you see in the image. However the water has a high concentration of Chlorine (900-1500mg/l) and I am thinking a steel ladder that stays in the water would be problematic. I thought about having a stackable one that could be installed to the ceiling but because of the PE cover, I am not sure because i can't weld the PE to the steel and ensure there won't be any H2 leakage to the concrete between PE and the ladder.

- We would like to have an automated element in tank in order to clean it and give the water a mix or even aerate time to time. Instead of an agitator, such a solution is being taught. But again it must be somehow installed to the ground or the wall that is covered with HDPE lining/coating.

Edit: I wrote we need an agitator but we don't have that intention anymore. Therefore, Point 3 is edited.

Attachments

Last edited: