fortjp500

Automotive

- Jun 22, 2021

- 15

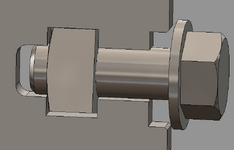

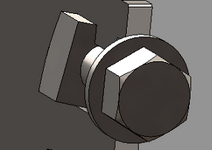

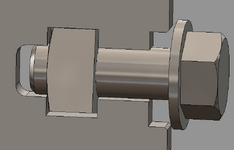

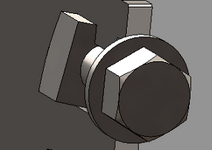

I saw this at work today. It's a .812 square nut (.413" deep/tall) in a slot that measures 0.875. The material is mild steel 1/4" thick. Calculating the shear from the clamp load is pretty straightforward. I'm wondering more about let's say the square nut and bolt threads are seized, and you apply removal torque. How does one calculate the max torque that the square cut can rotate against the sheet metal before it yields? Is there a conventional method that is straightforward, or would you just use FEA?