deemtocomply

Structural

- Feb 11, 2023

- 4

Hi gents,

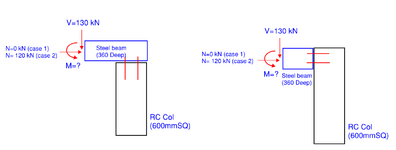

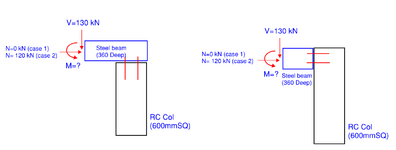

I have a UB steel beam connected to a reinforced concrete (RC) column, either positioned on top of the column or attached to its side. Based on my analysis, which assumes pin connections at the ends, I am obtaining the following design actions.

However, I believe both connection configurations, as shown below, will induce moments at the connection. When I model it as a rigid connection in my frame analysis, with the RC column having dimensions of 600x600, I am getting a large moment (about 80 kNm). I find it challenging to make the connection work with such high moments.

My questions are:

I have a UB steel beam connected to a reinforced concrete (RC) column, either positioned on top of the column or attached to its side. Based on my analysis, which assumes pin connections at the ends, I am obtaining the following design actions.

However, I believe both connection configurations, as shown below, will induce moments at the connection. When I model it as a rigid connection in my frame analysis, with the RC column having dimensions of 600x600, I am getting a large moment (about 80 kNm). I find it challenging to make the connection work with such high moments.

My questions are:

- Is modeling the steel beam–RC column connection as rigid in the frame analysis the correct approach to determine the end moment?

- Are there alternative connection methods you recommend that could make this design feasible?