I am simulating a rolling process of steel. The model is 3D with symmetry planes in Y and Z directions. I am using Abaqus Explicit for this. The height reduction of the material is high - around 80%. The simulation runs successfully, however mesh elements deform heavily, so I want to use adaptive mesh. The problem is that when I turn on ALE adaptive mesh, the simulation terminates shortly after the beginning.

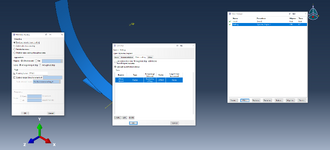

First, I will show you the case without adaptive meshing.

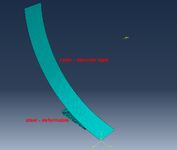

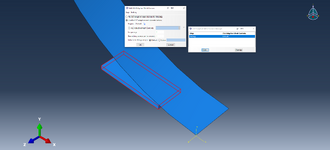

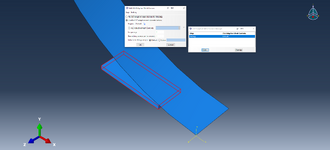

Before simulation:

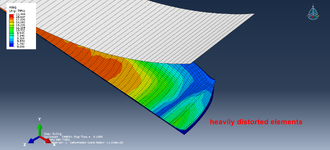

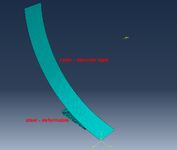

After simulation (elements are heavily distorted):

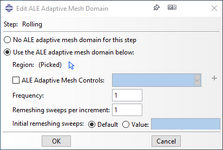

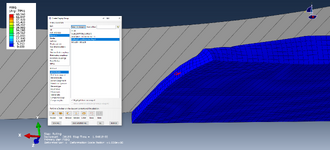

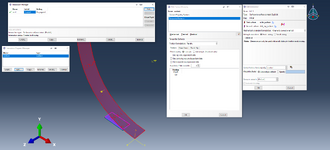

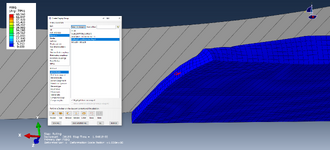

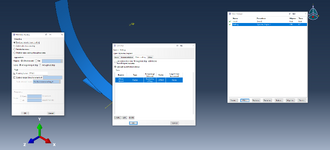

So, I turned on ALE adaptive mesh:

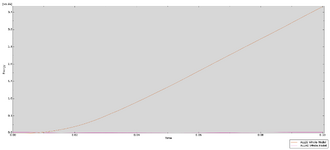

But the simulation terminates shortly after the start:

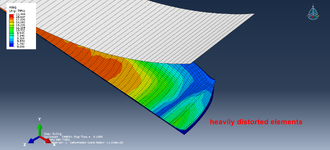

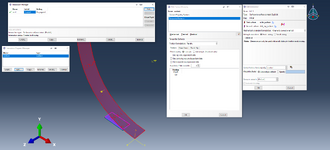

The results for the last successful increment are given below:

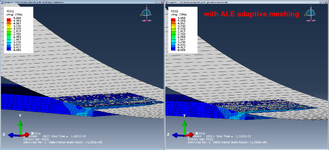

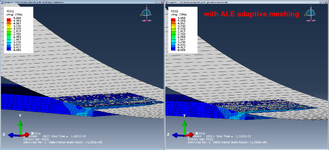

And the comparison between two simulations (with and without ALE adaptive meshing) at 0.015 step time (total time is 0.1):

It can be seen, that the quality of mesh improved.

I don’t understand, why the simulation with ALE adaptive mesh terminates. Shouldn’t it be opposite?

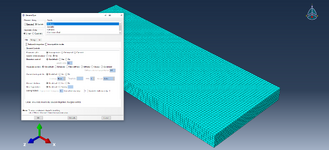

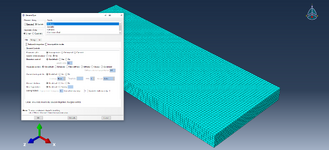

Some bonus images with additional information:

How can I solve this problem?

First, I will show you the case without adaptive meshing.

Before simulation:

After simulation (elements are heavily distorted):

So, I turned on ALE adaptive mesh:

But the simulation terminates shortly after the start:

The results for the last successful increment are given below:

And the comparison between two simulations (with and without ALE adaptive meshing) at 0.015 step time (total time is 0.1):

It can be seen, that the quality of mesh improved.

I don’t understand, why the simulation with ALE adaptive mesh terminates. Shouldn’t it be opposite?

Some bonus images with additional information:

How can I solve this problem?