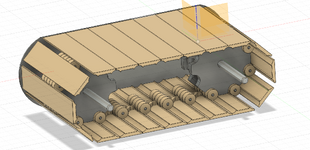

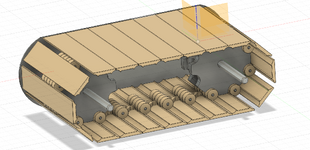

I am looking for feedback on this 3D conveyor belt I am designing. If people could give me feedback on things such as the design of my prototype, ways to connect the chain links (e.g. metal pins, lubrication, etc.), types of plastic to use, and whether or not this would even be possible in a real life scenario I would greatly appreciate it. I don't have a background in engineering, so feel free to tell me any mistakes I may have made and what I could do to improve my prototype.