PipesAndStuff

Civil/Environmental

- Apr 18, 2025

- 2

Hello,

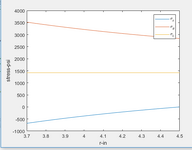

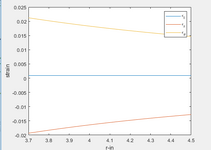

I'm determining the change in length of an 8-inch (DIPS) SDR11 HDPE pipe after pressurizing due the Poisson effect. I'm treating the pipe as a thick walled cylinder since the pipes diameter/thickness < 20.

I'm using the attached equations to compute axial, tangential, and radial stresses. Then computing the axial strain and multiplying by the pipe's length.

Here are the parameters:

Poison Ratio = 0.45

Elastic Modulus = 150,000 psi

Inside Radius = 3.7 inches

Outside Radius = 4.5 Inches

Inside Pressure = 180 psi

Pipe Length = 1000 ft

When I compute the stress for the inside wall of the pipe, I get a change in length of 29.1 Inches.

When I compute the stress for the outside wall of the pipe, I get a change in length of 2.9 inches.

I'm not sure which result to use or if I am approaching this problem correctly. I appreciate any insight people have for this problem.

Thanks,

Tony

I'm determining the change in length of an 8-inch (DIPS) SDR11 HDPE pipe after pressurizing due the Poisson effect. I'm treating the pipe as a thick walled cylinder since the pipes diameter/thickness < 20.

I'm using the attached equations to compute axial, tangential, and radial stresses. Then computing the axial strain and multiplying by the pipe's length.

Here are the parameters:

Poison Ratio = 0.45

Elastic Modulus = 150,000 psi

Inside Radius = 3.7 inches

Outside Radius = 4.5 Inches

Inside Pressure = 180 psi

Pipe Length = 1000 ft

When I compute the stress for the inside wall of the pipe, I get a change in length of 29.1 Inches.

When I compute the stress for the outside wall of the pipe, I get a change in length of 2.9 inches.

I'm not sure which result to use or if I am approaching this problem correctly. I appreciate any insight people have for this problem.

Thanks,

Tony