Ivan Silva

Industrial

- Dec 13, 2019

- 46

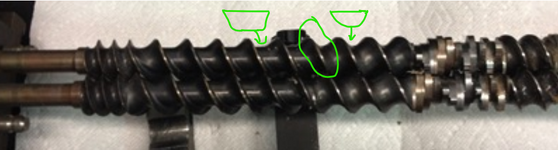

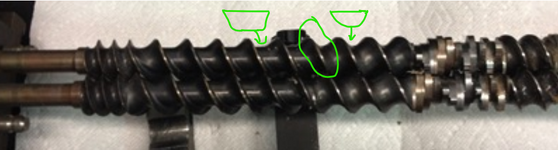

I'm currently trying to reverse engineering an 3d scanned based screw model. The profile section cut are pretty straightfoward to model but I have no idea how to model the transaction between two diferent cross-sections with different pitches in an smoth way.

Someone have ever experience to model an extruder screw like that?

Someone have ever experience to model an extruder screw like that?