timiacobucci

Automotive

I recently had an idea for a modification of an independent throttle body system to mimic the function of a variable geometry intake system simply using throttle opening.

Until recently I had not considered that part of the responsiveness of an itb system lies in the port velocity generated at part throttle opening. Aside from the possibly more turbulent airflow around the butterfly vs a specifically engineered multi runner variable geometry manifold this system actually seems it could be more advantageous in that it could vary the intake port area in a continuously variable way using the % throttle opening vs switch points for multiple runners in a traditional variable design. Obviously you could not tune runner length but port area and subsequently velocity has one of the biggest affects on intake charge tuning.

In normal itb operation with throttles which are sized such that they are not limiting vs the intake port size, after a certain throttle % opening at lower speeds the entire intake path is already at full atmospheric pressure(discounting forced induction for now). Say 20-40 % for the sake of argument. The remaining 60-80% of the throttle opening seems entirely unnecessary until the rpm and flow demands of the engine have caught up to the new port (throttle opening) area.

So my question is, is it possible there could be a benefit to intentionally limiting the actual itb opening at demanded full throttle to maintain a slight pressure drop across the throttle and maximize port velocity?

It seems like it would actually not be too difficult to do this all mechanically using a dual port diaphragm actuator on the throttle connected pre and post throttle and tuned via springs to bias the pressure drop/velocity desired.

Of course it may also be possible that optimal velocities are different at different rpm and load conditions and full electronic control would be beneficial but even a simple mechanical system as I described I suspect would be an easy enough way to test to viability of such a system before going into more sophisticated controls or tuning.

I find it hard to believe no one has experimented with this system before though, any knowledge of anyone else doing this before or if there is an inherent part I am missing as to why it wouldn't work?

I am curious how BMW has tuned their itbs on the newer throttle by wire m3s. Surely they would have discovered an advantage to be had if there was one right?

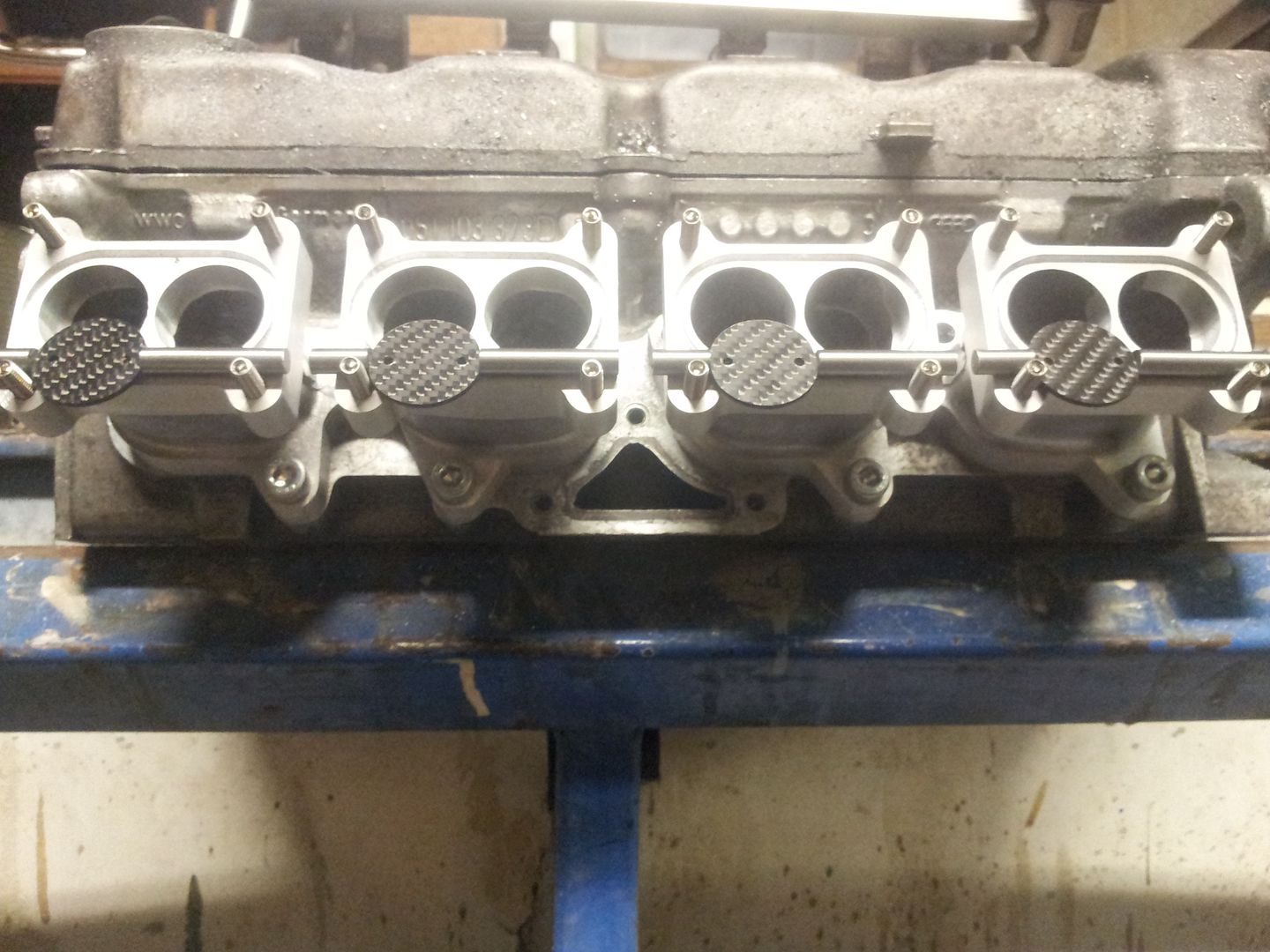

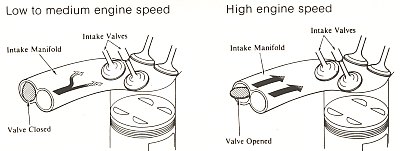

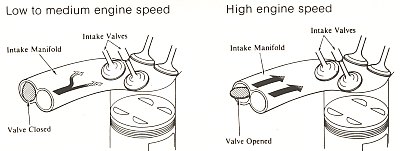

lastly, everybody likes pictures!

traditional toyota tvis

M3 ITB

Dual port interal wastegate actuator

Until recently I had not considered that part of the responsiveness of an itb system lies in the port velocity generated at part throttle opening. Aside from the possibly more turbulent airflow around the butterfly vs a specifically engineered multi runner variable geometry manifold this system actually seems it could be more advantageous in that it could vary the intake port area in a continuously variable way using the % throttle opening vs switch points for multiple runners in a traditional variable design. Obviously you could not tune runner length but port area and subsequently velocity has one of the biggest affects on intake charge tuning.

In normal itb operation with throttles which are sized such that they are not limiting vs the intake port size, after a certain throttle % opening at lower speeds the entire intake path is already at full atmospheric pressure(discounting forced induction for now). Say 20-40 % for the sake of argument. The remaining 60-80% of the throttle opening seems entirely unnecessary until the rpm and flow demands of the engine have caught up to the new port (throttle opening) area.

So my question is, is it possible there could be a benefit to intentionally limiting the actual itb opening at demanded full throttle to maintain a slight pressure drop across the throttle and maximize port velocity?

It seems like it would actually not be too difficult to do this all mechanically using a dual port diaphragm actuator on the throttle connected pre and post throttle and tuned via springs to bias the pressure drop/velocity desired.

Of course it may also be possible that optimal velocities are different at different rpm and load conditions and full electronic control would be beneficial but even a simple mechanical system as I described I suspect would be an easy enough way to test to viability of such a system before going into more sophisticated controls or tuning.

I find it hard to believe no one has experimented with this system before though, any knowledge of anyone else doing this before or if there is an inherent part I am missing as to why it wouldn't work?

I am curious how BMW has tuned their itbs on the newer throttle by wire m3s. Surely they would have discovered an advantage to be had if there was one right?

lastly, everybody likes pictures!

traditional toyota tvis

M3 ITB

Dual port interal wastegate actuator