The previous thread on window walls has been closed so I've had to create a new thread to continue this discussion.

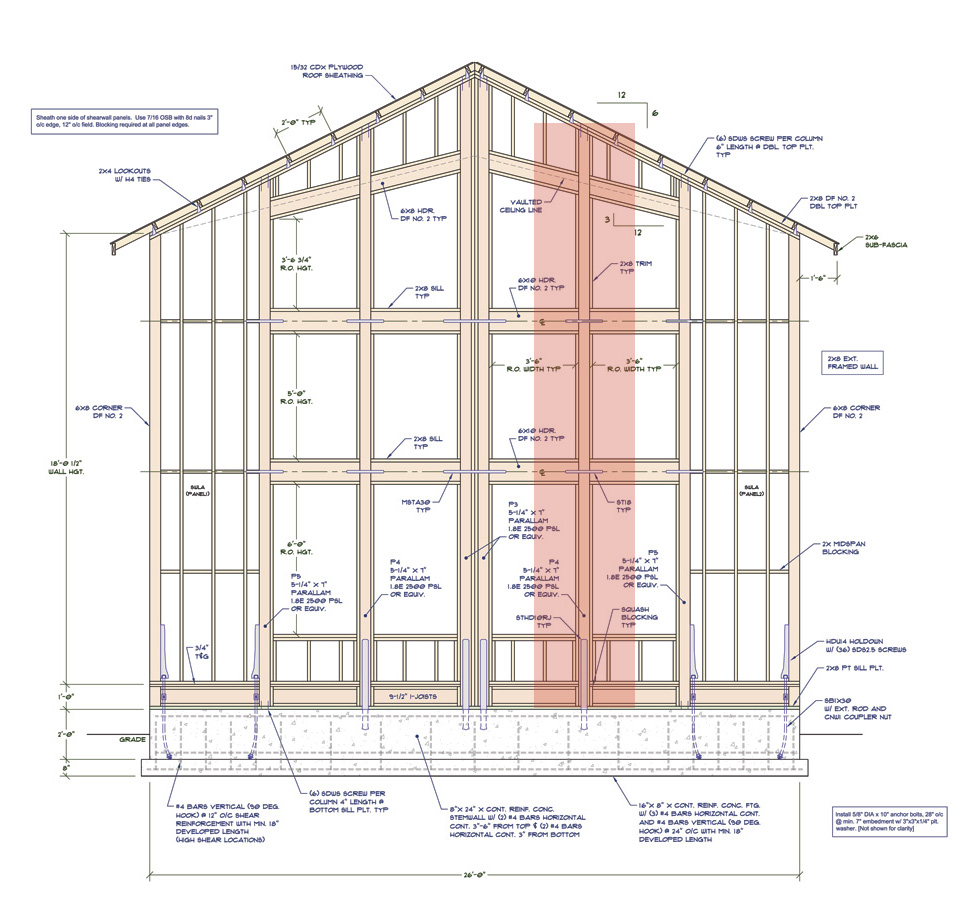

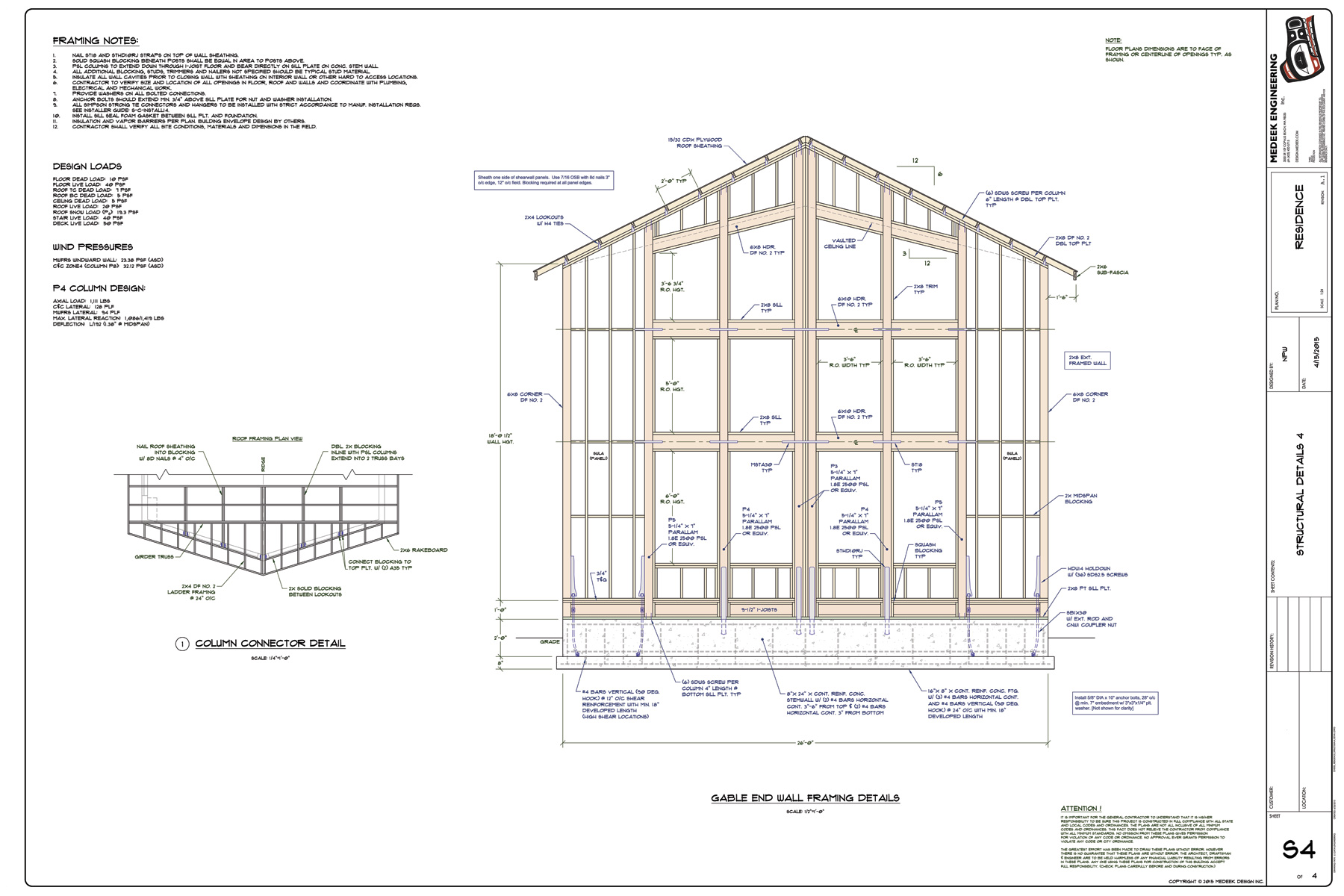

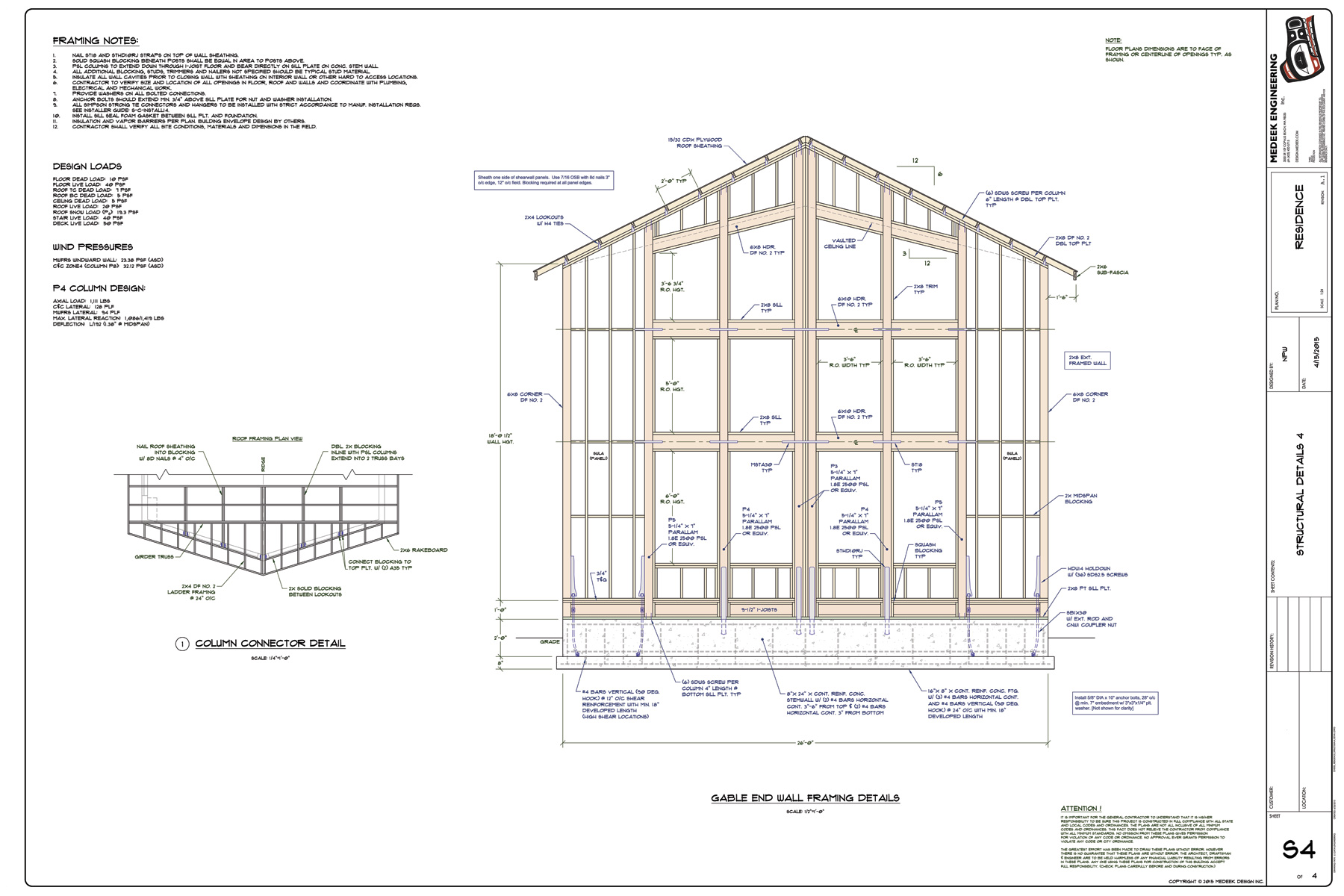

Apparently, these type of tall walls full of windows is the norm around here and not the exception (Ocean Shores Washington, beach homes). My most recent project involves a tall wall with windows as shown below:

I immediately went with a 2x8 stud wall due to the height and figured PSL columns in the wall should be the solution. After running the numbers I tentatively arrived at a 5-1/4"x7" PSL column for P4. The column in question, and the most critical column, is between both columns of windows and is approximately 22' tall. As far as strength I am good (40% in bending and 41% combined bending/axial), my concern is regarding the deflection at this column (midspan). According to my calculations using Forte I get a deflection of L/192 or approximately 1.38" at midspan. Typically I don't like to see a deflection over 0.5" (my hard deflection limit) but maybe this limit is unrealistic given the parameters and height of this wall.

Per the IBC/IRC deflection limits I should be okay (L/180 for gypsum walls) but a wall flexing in and out more than an inch seems highly problematic to me. I really don't want to go to a 2x10 stud wall but that may be my only option as I've pretty much reached the upper limit of wood performance with the PSL columns.

Has anyone integrated tried integrating steel columns into these type of walls?

Does anyone have any good resources on tall wall design and other tricks of the trade related to tall columns in walls that are controlled by deflections?

A confused student is a good student.

Nathaniel P. Wilkerson, PE

Apparently, these type of tall walls full of windows is the norm around here and not the exception (Ocean Shores Washington, beach homes). My most recent project involves a tall wall with windows as shown below:

I immediately went with a 2x8 stud wall due to the height and figured PSL columns in the wall should be the solution. After running the numbers I tentatively arrived at a 5-1/4"x7" PSL column for P4. The column in question, and the most critical column, is between both columns of windows and is approximately 22' tall. As far as strength I am good (40% in bending and 41% combined bending/axial), my concern is regarding the deflection at this column (midspan). According to my calculations using Forte I get a deflection of L/192 or approximately 1.38" at midspan. Typically I don't like to see a deflection over 0.5" (my hard deflection limit) but maybe this limit is unrealistic given the parameters and height of this wall.

Per the IBC/IRC deflection limits I should be okay (L/180 for gypsum walls) but a wall flexing in and out more than an inch seems highly problematic to me. I really don't want to go to a 2x10 stud wall but that may be my only option as I've pretty much reached the upper limit of wood performance with the PSL columns.

Has anyone integrated tried integrating steel columns into these type of walls?

Does anyone have any good resources on tall wall design and other tricks of the trade related to tall columns in walls that are controlled by deflections?

A confused student is a good student.

Nathaniel P. Wilkerson, PE