Pavan Kumar

Chemical

Hi All,

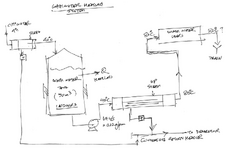

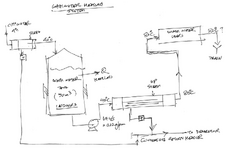

I am tasked to propose and design a Heating system for a Wash Water system. The system I am thinking is as shown in the below copied sketch. I want inputs from you all if there is a better or more efficient solution that mine. My task at this time is to propose a solution, get budgetary cost for the system involved namely - Storage Tank, Pumps, Heat Exchanger, Steam Boiler, Deaerator etc. The client after looking at various options and cost will decide on the best solution. If this option gets selected then I will do the detail engineering as well.

A storage tank that holds city water heated to 40 Deg C is passed through heat exchanger to 80 Deg C and supplied to the users. The wash water after passing through the users ( used for cleaning reactor kettles etc ) is sent to the sewer. I have to check if they have to get this water to 60 Deg C before sending it to the sewer. The City water supply is at 4 Deg C and heated to 40 Deg C using a Preheating Exchanger. A main heat exchanger that heats the water from 40 to 80 Deg C will be designed for the required flow rate of 14 Litre/sec (222 US gpm). The storage tank that will supply one hour's worth of water of 50 m3 will be sized. I have not yet done the calculations but with this system I see that the steam requirement will be very high and make it un-feasible. I want to know if there are better ways to do this.

Thanks and Regards,

Pavan Kumar

I am tasked to propose and design a Heating system for a Wash Water system. The system I am thinking is as shown in the below copied sketch. I want inputs from you all if there is a better or more efficient solution that mine. My task at this time is to propose a solution, get budgetary cost for the system involved namely - Storage Tank, Pumps, Heat Exchanger, Steam Boiler, Deaerator etc. The client after looking at various options and cost will decide on the best solution. If this option gets selected then I will do the detail engineering as well.

A storage tank that holds city water heated to 40 Deg C is passed through heat exchanger to 80 Deg C and supplied to the users. The wash water after passing through the users ( used for cleaning reactor kettles etc ) is sent to the sewer. I have to check if they have to get this water to 60 Deg C before sending it to the sewer. The City water supply is at 4 Deg C and heated to 40 Deg C using a Preheating Exchanger. A main heat exchanger that heats the water from 40 to 80 Deg C will be designed for the required flow rate of 14 Litre/sec (222 US gpm). The storage tank that will supply one hour's worth of water of 50 m3 will be sized. I have not yet done the calculations but with this system I see that the steam requirement will be very high and make it un-feasible. I want to know if there are better ways to do this.

Thanks and Regards,

Pavan Kumar