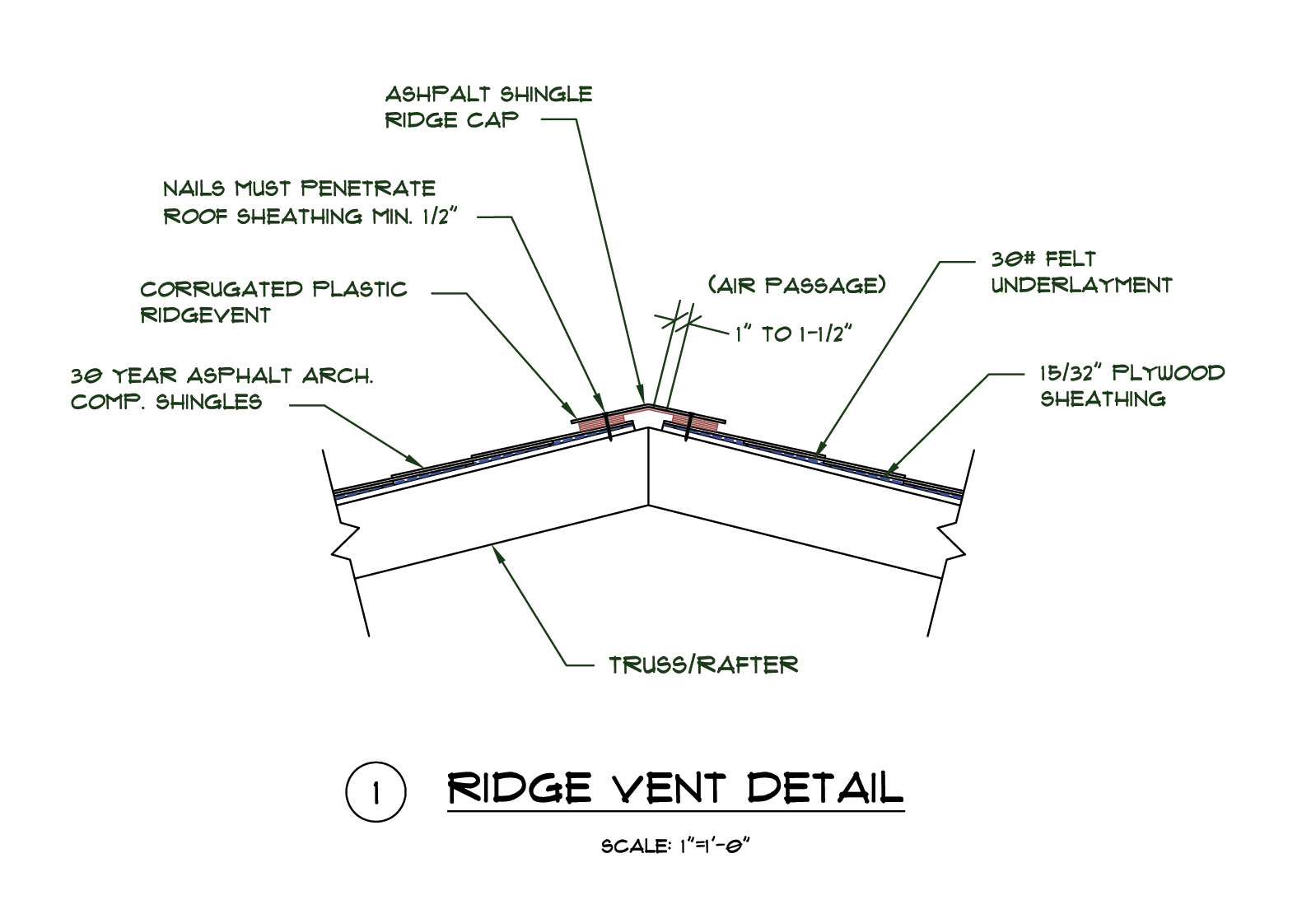

In my Breyer book they don't go into any detail about the discontinuities of a roof diaphragm at the ridge due to ventilation requirements. In the Breyer ridge detail (Page 9.28 Figure 9.10e of the 6th ed.) they show the sheathing as continuous. Not sure how that's realistic.

For the job I'm currently doing, I have a gable roof. The attic is finished so I was just going to use the rafters to transmit the lateral wind load into the attic floor diaphragm. But what if the attic is unfinished, how have some of you resolved this? Treat each roof face as two separate diaphragms?

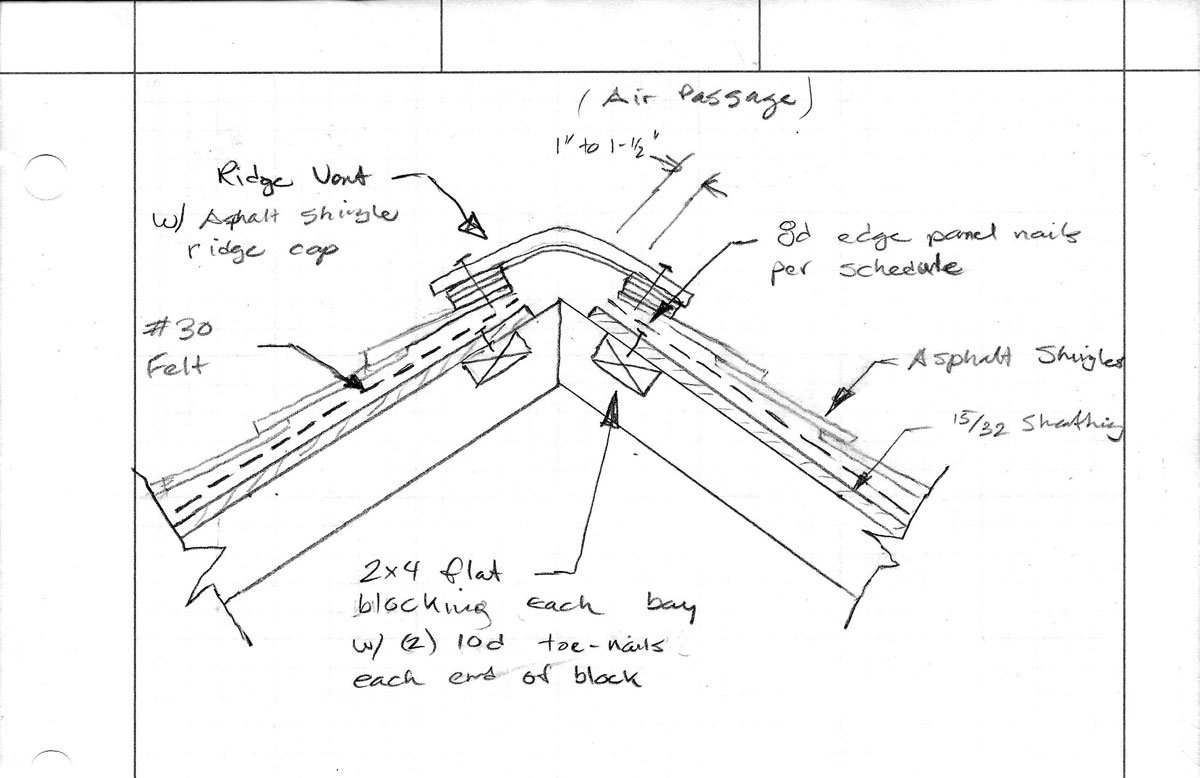

You could put blocking at the sheathing edge near the gap at he ridge, but this would disrupt air flow from the eave is the ceiling is finished. But I guess you have a finished ceiling, you'd have an attic floor to use as a diaphragm. So is that how you guys do it?

Curious as to what others do. Breyer advises to use "ATC Guidelines for Design of Horizontal Wood Diaphragms 1981" for steep roof diaphragms, I might have to pick it up. Anyone else us it?

Thanks

For the job I'm currently doing, I have a gable roof. The attic is finished so I was just going to use the rafters to transmit the lateral wind load into the attic floor diaphragm. But what if the attic is unfinished, how have some of you resolved this? Treat each roof face as two separate diaphragms?

You could put blocking at the sheathing edge near the gap at he ridge, but this would disrupt air flow from the eave is the ceiling is finished. But I guess you have a finished ceiling, you'd have an attic floor to use as a diaphragm. So is that how you guys do it?

Curious as to what others do. Breyer advises to use "ATC Guidelines for Design of Horizontal Wood Diaphragms 1981" for steep roof diaphragms, I might have to pick it up. Anyone else us it?

Thanks

![[lol] [lol] [lol]](/data/assets/smilies/lol.gif)