smb4050

Structural

- Jul 19, 2006

- 89

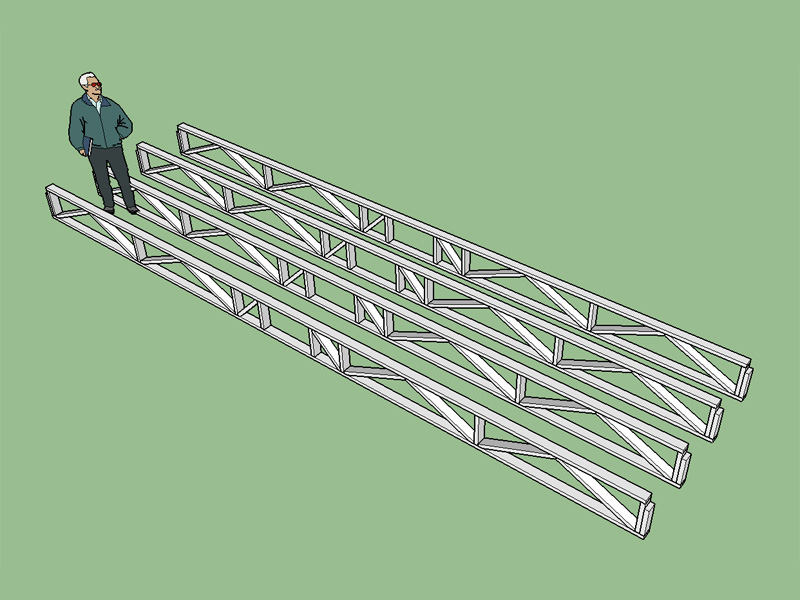

I have a small commercial building using bottom chord bearing open web wood joist @ 16" o.c. spanning 54' with 1/2":12" slope, and bearing on a 2x6 wood wall. Low side heel depth is 32"-36". Not sure what is the most common or economical means to transfer the horizontal diaphragm to the shear wall below. I'd use solid blocking with TJI or solid lumber joist, but the open web joist makes it more complicated. Local truss manufacturer suggested having them build a small framed box that fits between the trusses. Any suggestions or references will be appreciated. Thanks!