smokiibear

Structural

- Sep 19, 2006

- 158

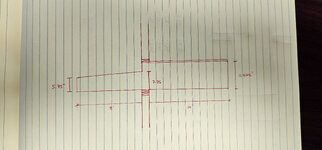

NDS says that notching for a beam at the bearing point can be 1/4 depth per Figure 4A, NDS 2018. Does this same figure apply when cantilevering a beam, for example a house to deck, where the notch would occur on the top face where the deck steps down. When cantilevering from house to deck the simple span portion would have unnotched bearing. Is there different criteria to follow?

Thanks,

Thanks,