Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This may be trickier than thought. I was involved with a court case about 50 years back regarding shear friction (not in the code yet) and the prof had run some finite element models, and the concrete bearing was in the order of 13ksi (hence failure)... He couldn't answer the question, "What happens if the concrete 'yields'."I would however try to check some sort of bearing stress limit between the anchor and the concrete when loaded in shear.

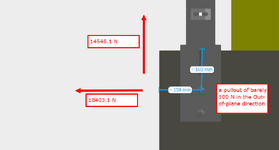

The idea is connecting a Section that is resisting Wind Loading the Calculations were done as a FEA and the Bolt is assumed to resist tension and shear both, the idea that the rotation will be bounded by the Grout.Is it loaded in shear or tension, or both?

I don't know about Eurocode, but in ACI I would treat this similarly to how anchors with structural adhesive are designed. Limit states for the anchor rod itself should be straight forward based on the diameter and material strength of the rod. Breakout in tension I would check with a punching shear calculation since the failure would be different than a breakout cone where the anchor doesn't extend through the full concrete thickness. Shear breakout is harder to envision in this scenario, if you aren't close to any free edges of the concrete I don't think this mechanism would develop; I would however try to check some sort of bearing stress limit between the anchor and the concrete when loaded in shear.

the stress area is a bit tricky to be honest as the effective length of the bolt is the total length of the Rod i am not sure if this will cause the Stress area to still be in the triangular shape or will it be uniform along the thickness of the Concrete@dik - Yes I think there is some gray area in trying to do a "bearing" check for the anchor loaded in shear. I'm not aware of a specific provision in ACI for this type of check on an anchor but I feel that it should be checked somehow. The trick is determining what an appropriate bearing area would be. I personally don't think you can justify using the entire length of the anchor for bearing, but admittedly I don't have any strong evidence to point to. The stress distribution is also problematic in the calculation (i.e. uniform, triangular, something else).

Curious on what others think about this....

i am also curious as if the concrete checks for the edge distance will be the same as anchor bolts as the more logical failure will be a blowout failure in the concrete@dik - Yes I think there is some gray area in trying to do a "bearing" check for the anchor loaded in shear. I'm not aware of a specific provision in ACI for this type of check on an anchor but I feel that it should be checked somehow. The trick is determining what an appropriate bearing area would be. I personally don't think you can justify using the entire length of the anchor for bearing, but admittedly I don't have any strong evidence to point to. The stress distribution is also problematic in the calculation (i.e. uniform, triangular, something else).

Curious on what others think about this....

it's loaded in both but i assume the major loading in this case will be the shear loading as it's only load is in the lateral directionWhat are the two (pink) serrated components under the left nut ?

Like TRAK said , "Is it loaded in shear or tension, or both?"

If the loading is in the up direction on your section than you may have edge distance problems. In this case I would consider having some rebar hairpins around the anchor group to prevent shear breakout of this section.View attachment 3461

A better section here showing the connection type the pink lines are the washer and the plate of the connection.

If the loading is in the up direction on your section than you may have edge distance problems. In this case I would consider having some rebar hairpins around the anchor group to prevent shear breakout of this section.

If it's loaded in shear, the through bolt gets its strength by tension. The grout has little to do with the strength.Like TRAK said , "Is it loaded in shear or tension, or both?"