Pavan Kumar

Chemical

- Aug 27, 2019

- 375

Hi All,

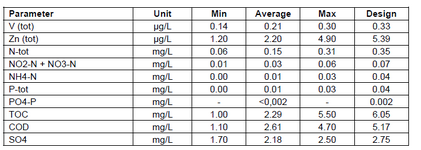

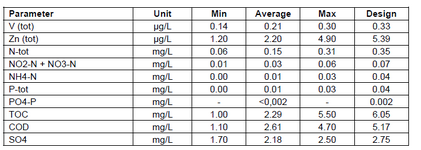

I have been asked to check the compatibility of Lean Duplex Steel for Industrial water, spec give below. I wanted to know how I can check this. On checking this forum I found that there is Langelier index which tells you if Caco3 will precipitate or not, but then how do you check if the material is suitable for this spec.

www.eng-tips.com

www.eng-tips.com

Thanks and Regards,

Pavan Kumar

I have been asked to check the compatibility of Lean Duplex Steel for Industrial water, spec give below. I wanted to know how I can check this. On checking this forum I found that there is Langelier index which tells you if Caco3 will precipitate or not, but then how do you check if the material is suitable for this spec.

Demin Water on carbon steel - Water treatment and distribution

I need advise how to deal with demin water (chemical additive??) so that it will not be too harse on carbon steel piping, without using stainless steel as an option?

Thanks and Regards,

Pavan Kumar