TRAK.Structural

Structural

- Dec 27, 2023

- 264

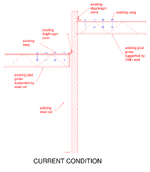

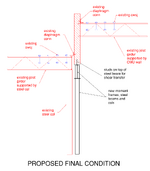

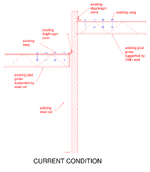

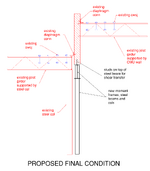

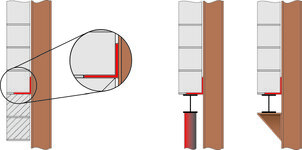

I have a potential project where the client wants to remove a portion of a CMU wall that separates different areas of an industrial building. The CMU wall is part of the lateral system for each side of the building so I am envisioning using either steel moment frames (or braced frames if I can convince them) in place of the wall in the final condition. The tricky part is that the upper portion of wall is going to remain. See my sketches below for the current condition and the proposed new condition. Design of the shoring and sequencing of the work will be up to the contractor but obviously I would have to come up with something that can indeed be built. Does this look reasonable? What pitfalls am I not thinking of?