plausibly_civil

Civil/Environmental

- Mar 15, 2024

- 17

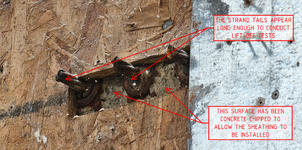

I am working on an existing building with three levels of elevated PT slabs. The building was built circa 2000 using unbonded PT tendons. The contractor is currently completing the strip portion of a full strip & reclad and discovered some PT tendons that appear to have never been cut or at least not capped during construction. The OSB sheathing at the third level was cut around the tendons and the tendons were butted up to/encapsulated in the exterior stucco. Has anyone seen a situation like this before? I was thinking about having them shear cut, cap, and grout the tendons for water protection after I was informed over the phone of the situation. However the damage looks more significant now that I have photos. The structure has performed fine for the last 25 years and the planned repairs to this building are mainly architectural, not due to structural distress. I'm wondering if we can arrest the damage at its current state without an intrusive repair and essentially abandon the tendons after cutting, cleaning, capping, and grouting. I worry about getting a good seal with the cap/grout given the damage to some of the wedge anchors, as well as the fact that there doesn't really appear to be a pocket to cap and grout.

Normally I have had tendons cut within 72 hours of the pour, followed by grease capping and grouting within a day. Are there any unintended consequences of cutting and capping the existing tendons now? Any thoughts to avoid an intrusive repair? My PT repair experience in the past has been all in new construction during CA. See attached photos for reference where the holes in the OSB are marked in red.

Normally I have had tendons cut within 72 hours of the pour, followed by grease capping and grouting within a day. Are there any unintended consequences of cutting and capping the existing tendons now? Any thoughts to avoid an intrusive repair? My PT repair experience in the past has been all in new construction during CA. See attached photos for reference where the holes in the OSB are marked in red.