ohstbuckz21

Structural

- Mar 20, 2025

- 2

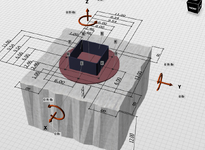

Running out of resources so looking for any and all opinions. Long story short, client has a existing structure design, rectangular HSS column with square base plate. (4) anchors, one in each corner, fairly standard. They want to redesign the baseplate to be round with (8) total holes, of which only (4) would be used at any given time, so they would be able to roate the structure 45 degrees in the field if needed. Pier foundations are installed ahead of time and they've run into issues where they are not aligned properly.

My question is, can this base plate be designed properly without the use of FEA? All design guides/resources I've come across have rightfully matched square with square, round with round and I'm hitting dead ends trying to marry rectangular column with round base plate. I think this is because it needs an FEA to design/analyze properly but looking for any input. Thanks in advance!

My question is, can this base plate be designed properly without the use of FEA? All design guides/resources I've come across have rightfully matched square with square, round with round and I'm hitting dead ends trying to marry rectangular column with round base plate. I think this is because it needs an FEA to design/analyze properly but looking for any input. Thanks in advance!