Hi there,

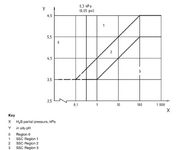

I'm strugling with the selection for a MPP pump for an onshore oil field(located in the rainforest), the plan is to pump a gas, liquid and oil mixture (about 60%GVF), as you can see i m a jr. engineer and i m having a lot of doubts. The physical-chemical production water test says that there is about 18 ppm H2S(g) and 10% CO2 (g) and the first question is about moc, the type of pump will be twin screw but in some part the API 676 says that if there is any % of H2S, the construction materials shall be suitable with NACE MR0175, but how can i know if the quantity of H2S is the amount enough for this kind of materials. To complete my confusion, i already receive two quotations, one from Bornemann and othrer from leistritz, the first one offers a NACE MR0175 design with reduced hardened materials, but the second only offers CS materials for internal parts as indicates that " materials will be confirmed once the fluid chemical properties are confirmed too". Thanks in advanve.

Similar, the API 676 says that NPSH test is not requerided for MPP, and also the quotations do not show any value for min NPSHr, so the question is ¿Does NPSH is a critical point for design in MPP pumps? ¿Why thes manufacturers do not indicate the amount of NPSHr? Is there any reference to check? because i already search a lot in the internet but i cant find this information. The second type of pump in case twin screw is not suitable, is PCP.

Total flow is about 30 300 bepd and water production flow is apprx. 4500 bwpd.

I'm strugling with the selection for a MPP pump for an onshore oil field(located in the rainforest), the plan is to pump a gas, liquid and oil mixture (about 60%GVF), as you can see i m a jr. engineer and i m having a lot of doubts. The physical-chemical production water test says that there is about 18 ppm H2S(g) and 10% CO2 (g) and the first question is about moc, the type of pump will be twin screw but in some part the API 676 says that if there is any % of H2S, the construction materials shall be suitable with NACE MR0175, but how can i know if the quantity of H2S is the amount enough for this kind of materials. To complete my confusion, i already receive two quotations, one from Bornemann and othrer from leistritz, the first one offers a NACE MR0175 design with reduced hardened materials, but the second only offers CS materials for internal parts as indicates that " materials will be confirmed once the fluid chemical properties are confirmed too". Thanks in advanve.

Similar, the API 676 says that NPSH test is not requerided for MPP, and also the quotations do not show any value for min NPSHr, so the question is ¿Does NPSH is a critical point for design in MPP pumps? ¿Why thes manufacturers do not indicate the amount of NPSHr? Is there any reference to check? because i already search a lot in the internet but i cant find this information. The second type of pump in case twin screw is not suitable, is PCP.

Total flow is about 30 300 bepd and water production flow is apprx. 4500 bwpd.