Fatihah Khalid

Mechanical

- Nov 7, 2024

- 1

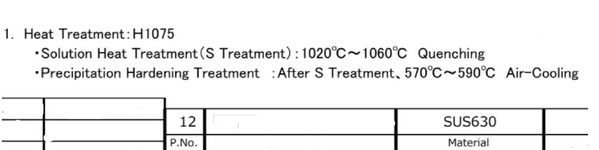

I have 1 part need to use 17-7PH and do treatment of H1025.

However, after machining very hard to control with this treatment and thus supplier propose to use pre heated material 17-4PH which comes along with H1025.

Is it possible? Do I need to check if the HRC of using 17-4PH is same as using 17-7PH?

However, after machining very hard to control with this treatment and thus supplier propose to use pre heated material 17-4PH which comes along with H1025.

Is it possible? Do I need to check if the HRC of using 17-4PH is same as using 17-7PH?