Hey all,

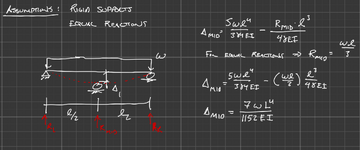

I am wondering if the 25% increase in reaction of the center support (compared to taking just trib widths) under a 2 span continuous beam, loaded via UDL, always occurs.

If the member was VERY stiff compared to the load, I'd imagine that the supports would be loaded more uniformly into a 25%/50%/25% split instead of 18.75%/62.5%/18.75%.

Furthermore, if you had a compressible support, for instance a wood post, as soon as the central post compresses at all wouldn't it re-distribute loads to the outer posts and find a nice equilibrium as a system.

I'm trying to get an exististing slab to work for a new mezzanine that is adding point loads from openings, but the LVL used was very deep for the load it actually carries (2ply 18" lvl only spanning 7ft). I'm considering adding a central post to alleviate the load on the slab edge, but then the central post gets loaded even heavier than without it.

I am wondering if the 25% increase in reaction of the center support (compared to taking just trib widths) under a 2 span continuous beam, loaded via UDL, always occurs.

If the member was VERY stiff compared to the load, I'd imagine that the supports would be loaded more uniformly into a 25%/50%/25% split instead of 18.75%/62.5%/18.75%.

Furthermore, if you had a compressible support, for instance a wood post, as soon as the central post compresses at all wouldn't it re-distribute loads to the outer posts and find a nice equilibrium as a system.

I'm trying to get an exististing slab to work for a new mezzanine that is adding point loads from openings, but the LVL used was very deep for the load it actually carries (2ply 18" lvl only spanning 7ft). I'm considering adding a central post to alleviate the load on the slab edge, but then the central post gets loaded even heavier than without it.

Last edited: