Challenging the DS1-CAT 3-5 Inspection findings that is failing most of our nearly new Drill pipe.

DS1 CAT 3-5 is the inspection criteria that's being used to inspect our drill string of 6-5/8" FH 34.2 lbs/ft VM-140 drill pipe.

8-1/2" OD tool joints 0.522 wall thickness tube.

Pin ID 4.25" Box ID 4.75".

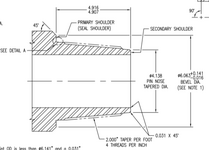

Does anyone have the minimum bevel OD criteria? TH Hill specs not 100% capturing the pipe specifications.

Drill pipe bevel wear, even though the bevel is an angle, the wear on the bevel can effect the connection seal face and is measured in OD.

DS1 CAT 3-5 is the inspection criteria that's being used to inspect our drill string of 6-5/8" FH 34.2 lbs/ft VM-140 drill pipe.

8-1/2" OD tool joints 0.522 wall thickness tube.

Pin ID 4.25" Box ID 4.75".

Does anyone have the minimum bevel OD criteria? TH Hill specs not 100% capturing the pipe specifications.

Drill pipe bevel wear, even though the bevel is an angle, the wear on the bevel can effect the connection seal face and is measured in OD.

Last edited: