fp23

Structural

- Aug 2, 2024

- 20

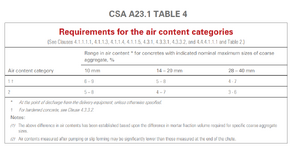

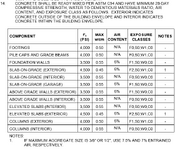

What do you all call out for air content in residential concrete? Specifically foundation walls and footings. I've been revamping my general notes and have seen other engineers specify no air, 5-6%, or not mention it at all. No air seems to be the most common.

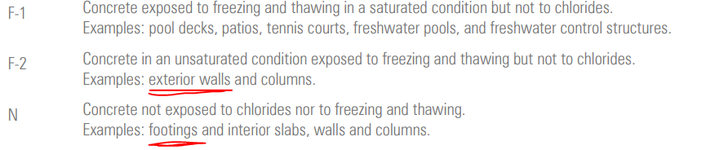

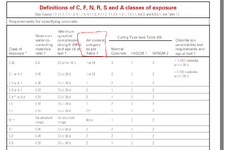

Based on the ACI I'm coming to the conclusion that footings and foundation walls should both be F1 at a minimum (maybe F2 for some foundation walls) and should have 5% air, although this feels a little conservative for the footings since they are at frost depth and the top of them probably won't see much freezing/thawing and/or water. Just curious if any of you have had pushback on this in the residential world.

Based on the ACI I'm coming to the conclusion that footings and foundation walls should both be F1 at a minimum (maybe F2 for some foundation walls) and should have 5% air, although this feels a little conservative for the footings since they are at frost depth and the top of them probably won't see much freezing/thawing and/or water. Just curious if any of you have had pushback on this in the residential world.