Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations MintJulep on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

aircraft passenger cabin stub beam

- Thread starter Green 123

- Start date

- Status

- Not open for further replies.

LiftDivergence

Aerospace

I understand the caution with this data and I also would not necessarily recommend posting the SB in a thread like this. Having said that, the SB is mandatorily incorporated by FAA final rule via AD and it is standard practice for the FAA to provide all data necessary for compliance with the AD on the federal register / AD docket. There is legal access to the SB at this location (.gov site): https://www.regulations.gov/document/FAA-2019-0249-0003.

Operators are under no legal obligation to use Boeing for the maintenance of their aircraft. It is perfectly legal for operators to use second or third tier parties for the continued airworthiness of aircraft and make use of the DER-T system. People like DERs, STC holders, etc. need access to this data since it is incorporated by reference in an AD, so the FAA publishes it. Anybody who has worked post-production support of transport category aircraft should be familiar with this.

Again, probably not a good idea to attach it here - instead in the future I would recommend linking to it like I did.

NOW, to discuss the topic, I think a key factor is that this is a superseding AD and incorporates a revision to the SB.

Basically a timeline of what happened:

1. Due to reports of cracking of the stub beams at certain areas, Boeing issued an SB 737-53A1364-00 which requires inspections and follow on instructions for repairs

2. As is standard practice, the SB makes provisions for the case that an existing approved repair is in the inspection area.

They further break this down based on some criteria for the repair. Because of the nature of the inspection they are doing (cracks emanating from an edge of the corner radius), their "ok" definition of repair would have trimmed out all the cracked material and installed a reinforcing repair with a filler. So if the repair meets SB internal definition of "ok", then you can do inspections of the outer repair holes per the SB. If those criteria are not met, the SB tells you to contact Boeing. (This is where non- Boeing post-production support approvals would need an AMOC). You can see their criteria for an "OK" repair per Part 3 3.B on page 62 of Rev 01 of the SB (see text below).

3. Eventually the FAA mandated these inspections via AD 2017-25-12

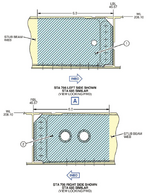

4. Later, the SB was revised by Boeing for several reasons, but chiefly to "Add [more/different] inspection of the stub beam at the inboard end of the upper chord, and the outboard end of the lower chord, at STA 685 and STA 706."

5. The FAA later superseded the previous AD with AD 2019-14-15 and incorporated Rev 01 of the SB by reference.

To accomplish Part 4 High Frequency Eddy Current (HFEC) inspection at the critical fastener

row in the stub beam common to the structural filler, the existing repair must have all of the

criteria that follows:

– The existing repair must have removed the radius detail of the lower inboard corner of

the stub beam web.

– The existing repair must be Boeing Organization Designation Authorization (ODA)

approved via an FAA Form 8100-9.

– The existing repair must have two 7075-T6 repair angles, 0.080 thick or greater, one

each side of the web.

– The existing repair angles must extend at least two rows beyond the web trim out in the

vertical and inboard directions, and the structural filler must extend at least one fastener

row beyond the repair angles.

– The existing repair upper row of fasteners must be 3/16 second oversize hi-loks or greater.

As such, what they mean when they say "The existing repair must have removed the radius detail of the lower inboard corner of the stub beam web" what they mean is that all of the cracked material should have been removed. The web will have been trimmed so that a "rectangular" segment including the radiused corner is absent. Then a filler and reinforcing repair (with it's own radius) has been installed. Effectively, the production geometry has been replace with repair material". In essence, a repair which did not trim out the damage before reinforcement would no be OK.

Operators are under no legal obligation to use Boeing for the maintenance of their aircraft. It is perfectly legal for operators to use second or third tier parties for the continued airworthiness of aircraft and make use of the DER-T system. People like DERs, STC holders, etc. need access to this data since it is incorporated by reference in an AD, so the FAA publishes it. Anybody who has worked post-production support of transport category aircraft should be familiar with this.

Again, probably not a good idea to attach it here - instead in the future I would recommend linking to it like I did.

NOW, to discuss the topic, I think a key factor is that this is a superseding AD and incorporates a revision to the SB.

Basically a timeline of what happened:

1. Due to reports of cracking of the stub beams at certain areas, Boeing issued an SB 737-53A1364-00 which requires inspections and follow on instructions for repairs

2. As is standard practice, the SB makes provisions for the case that an existing approved repair is in the inspection area.

They further break this down based on some criteria for the repair. Because of the nature of the inspection they are doing (cracks emanating from an edge of the corner radius), their "ok" definition of repair would have trimmed out all the cracked material and installed a reinforcing repair with a filler. So if the repair meets SB internal definition of "ok", then you can do inspections of the outer repair holes per the SB. If those criteria are not met, the SB tells you to contact Boeing. (This is where non- Boeing post-production support approvals would need an AMOC). You can see their criteria for an "OK" repair per Part 3 3.B on page 62 of Rev 01 of the SB (see text below).

3. Eventually the FAA mandated these inspections via AD 2017-25-12

4. Later, the SB was revised by Boeing for several reasons, but chiefly to "Add [more/different] inspection of the stub beam at the inboard end of the upper chord, and the outboard end of the lower chord, at STA 685 and STA 706."

5. The FAA later superseded the previous AD with AD 2019-14-15 and incorporated Rev 01 of the SB by reference.

To accomplish Part 4 High Frequency Eddy Current (HFEC) inspection at the critical fastener

row in the stub beam common to the structural filler, the existing repair must have all of the

criteria that follows:

– The existing repair must have removed the radius detail of the lower inboard corner of

the stub beam web.

– The existing repair must be Boeing Organization Designation Authorization (ODA)

approved via an FAA Form 8100-9.

– The existing repair must have two 7075-T6 repair angles, 0.080 thick or greater, one

each side of the web.

– The existing repair angles must extend at least two rows beyond the web trim out in the

vertical and inboard directions, and the structural filler must extend at least one fastener

row beyond the repair angles.

– The existing repair upper row of fasteners must be 3/16 second oversize hi-loks or greater.

As such, what they mean when they say "The existing repair must have removed the radius detail of the lower inboard corner of the stub beam web" what they mean is that all of the cracked material should have been removed. The web will have been trimmed so that a "rectangular" segment including the radiused corner is absent. Then a filler and reinforcing repair (with it's own radius) has been installed. Effectively, the production geometry has been replace with repair material". In essence, a repair which did not trim out the damage before reinforcement would no be OK.

- Thread starter

- #22

The SB is incorporated by reference in FAA AD 2019-14-15 and so its content is available for free online from following link:

www.regulations.gov

www.regulations.gov

Regulations.gov

- Thread starter

- #23

- Thread starter

- #24

I really appreciate your explanationI understand the caution with this data and I also would not necessarily recommend posting the SB in a thread like this. Having said that, the SB is mandatorily incorporated by FAA final rule via AD and it is standard practice for the FAA to provide all data necessary for compliance with the AD on the federal register / AD docket. There is legal access to the SB at this location (.gov site): https://www.regulations.gov/document/FAA-2019-0249-0003.

Operators are under no legal obligation to use Boeing for the maintenance of their aircraft. It is perfectly legal for operators to use second or third tier parties for the continued airworthiness of aircraft and make use of the DER-T system. People like DERs, STC holders, etc. need access to this data since it is incorporated by reference in an AD, so the FAA publishes it. Anybody who has worked post-production support of transport category aircraft should be familiar with this.

Again, probably not a good idea to attach it here - instead in the future I would recommend linking to it like I did.

NOW, to discuss the topic, I think a key factor is that this is a superseding AD and incorporates a revision to the SB.

Basically a timeline of what happened:

1. Due to reports of cracking of the stub beams at certain areas, Boeing issued an SB 737-53A1364-00 which requires inspections and follow on instructions for repairs

2. As is standard practice, the SB makes provisions for the case that an existing approved repair is in the inspection area.

They further break this down based on some criteria for the repair. Because of the nature of the inspection they are doing (cracks emanating from an edge of the corner radius), their "ok" definition of repair would have trimmed out all the cracked material and installed a reinforcing repair with a filler. So if the repair meets SB internal definition of "ok", then you can do inspections of the outer repair holes per the SB. If those criteria are not met, the SB tells you to contact Boeing. (This is where non- Boeing post-production support approvals would need an AMOC). You can see their criteria for an "OK" repair per Part 3 3.B on page 62 of Rev 01 of the SB (see text below).

3. Eventually the FAA mandated these inspections via AD 2017-25-12

4. Later, the SB was revised by Boeing for several reasons, but chiefly to "Add [more/different] inspection of the stub beam at the inboard end of the upper chord, and the outboard end of the lower chord, at STA 685 and STA 706."

5. The FAA later superseded the previous AD with AD 2019-14-15 and incorporated Rev 01 of the SB by reference.

To accomplish Part 4 High Frequency Eddy Current (HFEC) inspection at the critical fastener

row in the stub beam common to the structural filler, the existing repair must have all of the

criteria that follows:

– The existing repair must have removed the radius detail of the lower inboard corner of

the stub beam web.

– The existing repair must be Boeing Organization Designation Authorization (ODA)

approved via an FAA Form 8100-9.

– The existing repair must have two 7075-T6 repair angles, 0.080 thick or greater, one

each side of the web.

– The existing repair angles must extend at least two rows beyond the web trim out in the

vertical and inboard directions, and the structural filler must extend at least one fastener

row beyond the repair angles.

– The existing repair upper row of fasteners must be 3/16 second oversize hi-loks or greater.

As such, what they mean when they say "The existing repair must have removed the radius detail of the lower inboard corner of the stub beam web" what they mean is that all of the cracked material should have been removed. The web will have been trimmed so that a "rectangular" segment including the radiused corner is absent. Then a filler and reinforcing repair (with it's own radius) has been installed. Effectively, the production geometry has been replace with repair material". In essence, a repair which did not trim out the damage before reinforcement would no be OK.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 7K

- Replies

- 4

- Views

- 10K

- Replies

- 33

- Views

- 16K

- Question

- Replies

- 50

- Views

- 36K

- Locked

- Question

- Replies

- 13

- Views

- 6K