wayne_dwops

Structural

I know you could knit a sweater with all the threads on this topic but I am still not satisfied with what I've found. I am hoping for a sanity check.

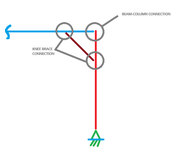

I have modeled an open (25'x15'x13'), wood framed, pitched ramada structure with a tile finish, king posts and knee braces in RISA-3D. As expected, gravity (D + RLL) is inducing intense axial forces through the knee braces and beams, far more than lateral. For discussion's sake, my model states I am throwing 4k axial compression through the brace, and 2.4k axial tension through the beam-column connection for a structure framed 8x lumber. A quick hand calc for lateral loads results in a worst case of about 0.5k per frame I am resisting under lateral load conditions.

Past forum posts suggest neglecting the effects of gravity on the knee braces. I consider this a viable solution to slimming down my connection design, in lieu of stiffening my beams or otherwise modifying the geometry/fixities of the structure. My problem is as follows: In my head, I can't resolve the behavior of a knee brace designed only for the effects of lateral load with how I expect the structure will behave once erected. Mechanics dictates that the brace will try to resist gravity load effects, attempting to approach my RISA-3D model results. Is there a way to design the connections so that the joint can accommodate the clear span gravity deflection of the beams, while still providing support for lateral load effects? A quick web search of these structures does not yield any overly complicated fastening details, rather they all look incredibly simple. What have you done in this situation? Am I way off base?

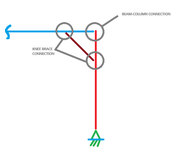

One immediate thought I have is to allow the dead load deflection to set in before installing the braces, but roof live load effects alone still outweigh the lateral load I am putting through this connection. It may be that I just need to beef up the beams to attract less load to the braces. I've attached an elevation of a knee brace below.

Thank you in advance.

I have modeled an open (25'x15'x13'), wood framed, pitched ramada structure with a tile finish, king posts and knee braces in RISA-3D. As expected, gravity (D + RLL) is inducing intense axial forces through the knee braces and beams, far more than lateral. For discussion's sake, my model states I am throwing 4k axial compression through the brace, and 2.4k axial tension through the beam-column connection for a structure framed 8x lumber. A quick hand calc for lateral loads results in a worst case of about 0.5k per frame I am resisting under lateral load conditions.

Past forum posts suggest neglecting the effects of gravity on the knee braces. I consider this a viable solution to slimming down my connection design, in lieu of stiffening my beams or otherwise modifying the geometry/fixities of the structure. My problem is as follows: In my head, I can't resolve the behavior of a knee brace designed only for the effects of lateral load with how I expect the structure will behave once erected. Mechanics dictates that the brace will try to resist gravity load effects, attempting to approach my RISA-3D model results. Is there a way to design the connections so that the joint can accommodate the clear span gravity deflection of the beams, while still providing support for lateral load effects? A quick web search of these structures does not yield any overly complicated fastening details, rather they all look incredibly simple. What have you done in this situation? Am I way off base?

One immediate thought I have is to allow the dead load deflection to set in before installing the braces, but roof live load effects alone still outweigh the lateral load I am putting through this connection. It may be that I just need to beef up the beams to attract less load to the braces. I've attached an elevation of a knee brace below.

Thank you in advance.