Hi,

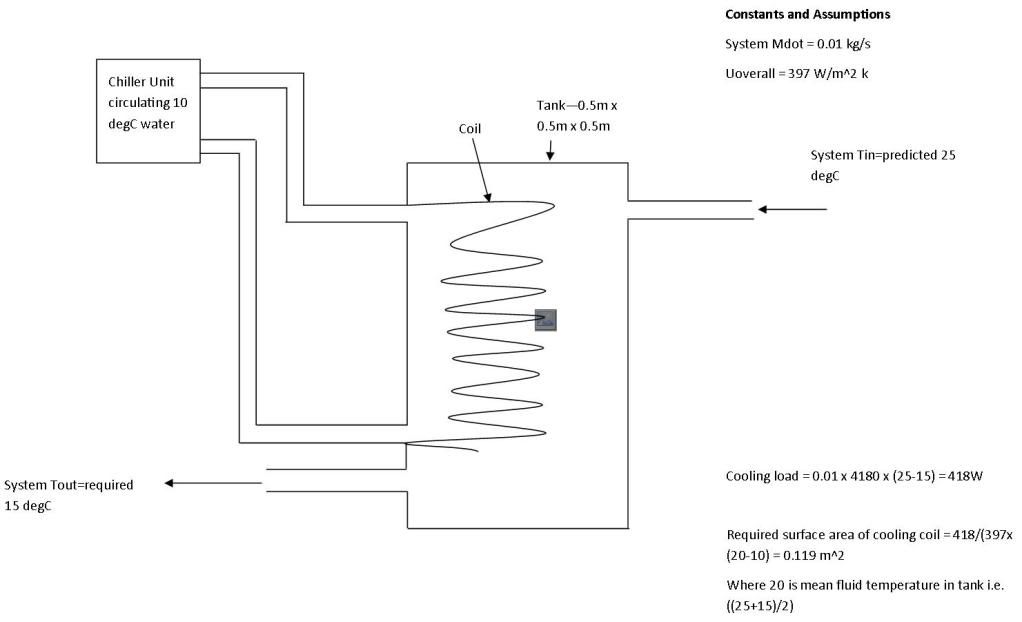

I am looking to size a copper coil to cool a volume of water by 5-10 degC. I have found numerous examples for heat exchanger calculations. The volume of water does have an inlet and an outlet but it is very slow so should this be treated as a batch cooling problem (think this is how they are referred to)?

All the equations I have found require an known value that I don't have. This PDF

was helpful but I want to consider a steady state problem as I desire a constant outlet temperature from the bottom of the tank.

Any help, most appreciated. I think I just need pointing in the right direction.

I am looking to size a copper coil to cool a volume of water by 5-10 degC. I have found numerous examples for heat exchanger calculations. The volume of water does have an inlet and an outlet but it is very slow so should this be treated as a batch cooling problem (think this is how they are referred to)?

All the equations I have found require an known value that I don't have. This PDF

was helpful but I want to consider a steady state problem as I desire a constant outlet temperature from the bottom of the tank.

Any help, most appreciated. I think I just need pointing in the right direction.

![[hammer] [hammer] [hammer]](/data/assets/smilies/hammer.gif)