Hello to all,

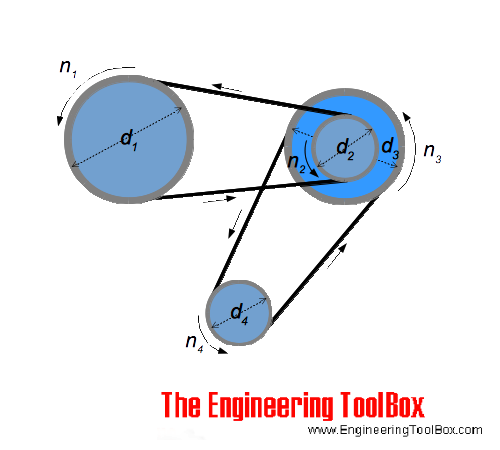

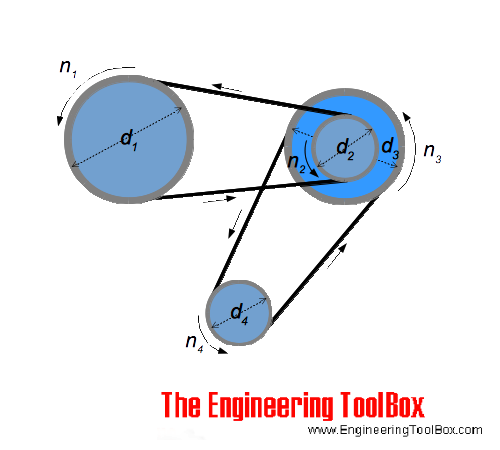

I had a discussion with my coworkers about a brake disc grinding machine that is pretty old, regarding the optimum diameter of driver pulley. We will put a new EM on it together with new driver pulley. We have the info from the grinding disc manufacturer about maximum allowed tangential speed (= 30 m/s). The whole transmission system is similar to the one in the added picture, except that in our case diameter d2=d3 and the diameter of the grinding disc with diamond powder is lets say d5. The question is what is the right diameter of the driver pulley (d1) directly from EM in order to get tangential speed of 30m/s on the d5 (grind disc) diameter? I calculated it to be around 200mm, but my coworkers think it should be smaller (currently it is around 90mm).

We know that:

n1= 2900 RPM

d2=d3=76mm --> (machine grinds both sides of brake disc at the same time, pulley #2 is in the middle of the shaft with same diameter that has two belts connected for each side)

d4=55mm

d5 (grinding disc)=200mm

vtangential=30m/s.

Any ideas what the right diameter d1 should be?

Thank you!

I had a discussion with my coworkers about a brake disc grinding machine that is pretty old, regarding the optimum diameter of driver pulley. We will put a new EM on it together with new driver pulley. We have the info from the grinding disc manufacturer about maximum allowed tangential speed (= 30 m/s). The whole transmission system is similar to the one in the added picture, except that in our case diameter d2=d3 and the diameter of the grinding disc with diamond powder is lets say d5. The question is what is the right diameter of the driver pulley (d1) directly from EM in order to get tangential speed of 30m/s on the d5 (grind disc) diameter? I calculated it to be around 200mm, but my coworkers think it should be smaller (currently it is around 90mm).

We know that:

n1= 2900 RPM

d2=d3=76mm --> (machine grinds both sides of brake disc at the same time, pulley #2 is in the middle of the shaft with same diameter that has two belts connected for each side)

d4=55mm

d5 (grinding disc)=200mm

vtangential=30m/s.

Any ideas what the right diameter d1 should be?

Thank you!