rllo

Civil/Environmental

- Mar 25, 2021

- 7

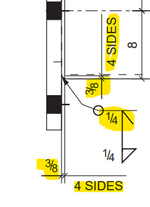

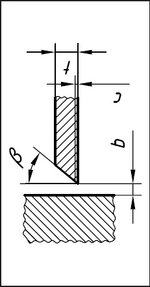

I have a question about beveling specifically. a 1/4" bevel weld was called out to attach a HSS16x16x1/2 to PL. the shop drawings show a 3/8" chamfer (bevel?) on all 4 sides. why is that? I drew this up in CAD and don't see where my 1/4" bevel spec is. then I realized I don't really know what I'm doing - is the 1/4" bevel supposed to be the leg or hypotenuse distance, I wondered. this is why i'm here. thank you for your help.