human909

Structural

- Mar 19, 2018

- 2,112

I hope the title caught you attention, and I hope you are enthused to have your thinking caps on.

So we as good engineers know that, we should use thick/(or gusseted) plates when we are designing connections with significant tension loads. A big part of this is so we can use a rigid plate approach and simplify connection design and reduce prying forces on our bolts.

But what about when we don't have a rigid connection under tension? What do we want to accept as satisfactory?

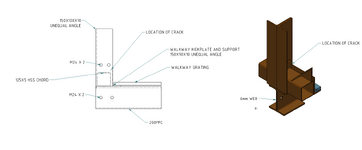

Exhibit A:

This is the bottom chord and walkway of a 20m truss gantry. This is a very ugly connection under tension as it is the bottom chord.

The bottom chord is HSS(125x125mm) and the verticals are 125x10Angle. 2xM24 bolts above and below the HSS chord. It is pretty clear that the 10mm plate section of the angle isn't stiff enough for the load here. (At a guess 25mm plate would be better)

This deflection is under dead weight only (which is about 80% of service load and 40% of ultimate load.) Bolts even with prying are more than satisfactory and the plate is unlikely to fail (I have yet to explicitly calc this out). How would you deal with this situation? Would you reject it? Perform significant rectification? Accept it if it calcs out?

Any thoughts appreciated.

So we as good engineers know that, we should use thick/(or gusseted) plates when we are designing connections with significant tension loads. A big part of this is so we can use a rigid plate approach and simplify connection design and reduce prying forces on our bolts.

But what about when we don't have a rigid connection under tension? What do we want to accept as satisfactory?

Exhibit A:

This is the bottom chord and walkway of a 20m truss gantry. This is a very ugly connection under tension as it is the bottom chord.

The bottom chord is HSS(125x125mm) and the verticals are 125x10Angle. 2xM24 bolts above and below the HSS chord. It is pretty clear that the 10mm plate section of the angle isn't stiff enough for the load here. (At a guess 25mm plate would be better)

This deflection is under dead weight only (which is about 80% of service load and 40% of ultimate load.) Bolts even with prying are more than satisfactory and the plate is unlikely to fail (I have yet to explicitly calc this out). How would you deal with this situation? Would you reject it? Perform significant rectification? Accept it if it calcs out?

Any thoughts appreciated.