BacBac

Structural

- Aug 11, 2024

- 25

Hi All,

Does anyone know why the effect of edge breakout is more severe in post-fixed rebar with epoxy compared to cast-in rebar?

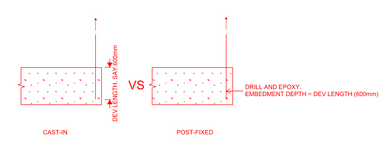

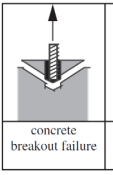

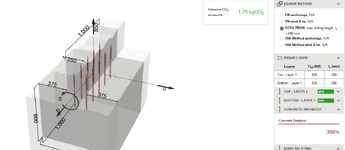

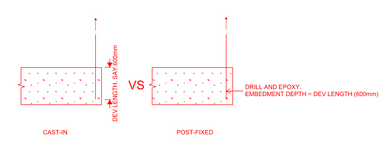

Say you're drilling a post-fixed rebar the same length as what the development length of the cast-in rebar, if you check it in Hilti or similar software, the capacity will not be even close to the yield capacity of the cast-in rebar due to edge breakout failure. While in cast-in rebar, there is no edge breakout if you embed the bar as development length. Please see snapshot below for clarity.

I'm asking this because there's a site issue with missing wall starter bars, and the wall is in tension at its edge. The post-fixed rebar needs to reach its yield strength to resist the tension demand.

Thanks in advance!

Does anyone know why the effect of edge breakout is more severe in post-fixed rebar with epoxy compared to cast-in rebar?

Say you're drilling a post-fixed rebar the same length as what the development length of the cast-in rebar, if you check it in Hilti or similar software, the capacity will not be even close to the yield capacity of the cast-in rebar due to edge breakout failure. While in cast-in rebar, there is no edge breakout if you embed the bar as development length. Please see snapshot below for clarity.

I'm asking this because there's a site issue with missing wall starter bars, and the wall is in tension at its edge. The post-fixed rebar needs to reach its yield strength to resist the tension demand.

Thanks in advance!