CraigRochester

Mechanical

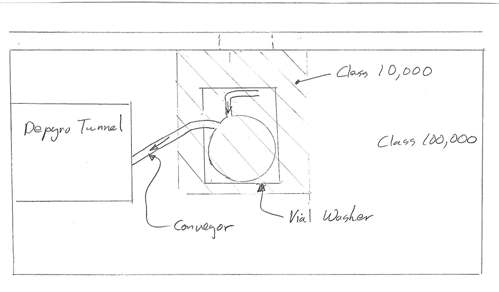

I have a vial washing machine that uses hot water spray. Vials go in and out of the machine through "mouse holes". The aerosol laden and ~ 100F/100%RH excapes into the class 10K zone --> not good. This was not considered in the room/equip design.

I cannot ventilate normally with ducted exhaust because the duct would obstruct the HEPA coverage above and along the floor would be a tripping hazard.

I'm thinking of a refrigeration dehumidifier with ~20 CFM flow. I would direct the dry cool air back to the room and drain the condensate/aerosols.

Does this exist? Any other ideas?

Thanks in advance,

Craig

I cannot ventilate normally with ducted exhaust because the duct would obstruct the HEPA coverage above and along the floor would be a tripping hazard.

I'm thinking of a refrigeration dehumidifier with ~20 CFM flow. I would direct the dry cool air back to the room and drain the condensate/aerosols.

Does this exist? Any other ideas?

Thanks in advance,

Craig