CollinW

Structural

- Mar 9, 2023

- 10

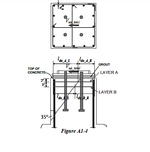

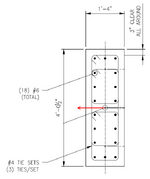

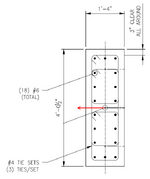

I feel like I am going crazy trying to reinvent the wheel so I wanted some additional advice. My office has a detail that they have used a couple of times. It is a pedestal that sees large shears mostly through pipe friction. The pedestal and footing are joined at a construction joint and designed per ACI. I have a few questions, but any insight helps:

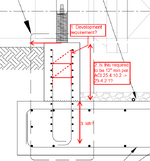

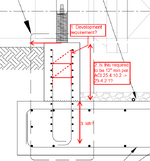

1. Is there special detail required at the top of the longitudinal pedestal rebar. I have never seen any special detail on pedestals like this, but the bars technically have no development at the top. In corbel design there are often special detailing as this tension bar would be welded or specially attached. Why is that not required here?

2. ACI 25.4.2.1 states that the minimum development length is 12", so does that mean that the minimum pedestal height is 12". At the top of the pedestal the actual development length is 0 and the As,req is also 0 (no moment). So per ACI 25.4.10.2 you can reduce the development length, but to a min of 12". This whole thing feels weird because making the pedestal longer also increases the moment. Do we even need to develop these bars at all? I want to say we do if we have the construction joint, but we can potentially remove this if needed. ACI 22.5.1 for shear friction requires full development on either side.

3. Is it adequate to just develop pedestal rebar vertically in the footing? There was a long thread here discussing T-joints and I understand the idea of bending the bars and lapping them horizontally. But when the footing is thick enough, can't we just develop them vertically? Maybe we should check the rebar for a breakout cone/anchorage, but other than that I don't see any issues.

1. Is there special detail required at the top of the longitudinal pedestal rebar. I have never seen any special detail on pedestals like this, but the bars technically have no development at the top. In corbel design there are often special detailing as this tension bar would be welded or specially attached. Why is that not required here?

2. ACI 25.4.2.1 states that the minimum development length is 12", so does that mean that the minimum pedestal height is 12". At the top of the pedestal the actual development length is 0 and the As,req is also 0 (no moment). So per ACI 25.4.10.2 you can reduce the development length, but to a min of 12". This whole thing feels weird because making the pedestal longer also increases the moment. Do we even need to develop these bars at all? I want to say we do if we have the construction joint, but we can potentially remove this if needed. ACI 22.5.1 for shear friction requires full development on either side.

3. Is it adequate to just develop pedestal rebar vertically in the footing? There was a long thread here discussing T-joints and I understand the idea of bending the bars and lapping them horizontally. But when the footing is thick enough, can't we just develop them vertically? Maybe we should check the rebar for a breakout cone/anchorage, but other than that I don't see any issues.

Last edited: