Dear all,

I am currently designing a hairpin heat exchanger under ASME VIII-1 Ed. 2023 with the following design conditions:

Moreover, a joint efficiency lower than the effective control could be dangerous and impact the integrity of the design. Therefore, I would like to clarify if such an approach can be accepted or if it will require further adjustments.

Additionally, I referred to the following ASME Interpretations for further clarification:

Thank you for your guidance!

I am currently designing a hairpin heat exchanger under ASME VIII-1 Ed. 2023 with the following design conditions:

- Corrosion Allowance: 1.6 mm

- Shell Side Pressure: 10 barg, Temperature: 280°C

- Tube Side Pressure: 93 barg, Temperature: 280°C

- Joint Efficiency Required by Client: FULL

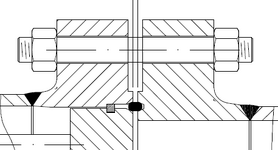

- This type of joint, under UG-34, might be considered with a joint efficiency of 1.0 for design purposes (i.e., no joint efficiency is required, see interpretation below, despite a factor E, joint efficiency is taken into account in the required thickness calculation).

- If all requirements of UW-13(e) are met, and all inspections under UG-93(d) are performed, could this joint be effectively assigned a joint efficiency of 1.0, thus allowing us to categorize the nameplate joint efficiency and extension of radiograpy as RT1 or RT2 (even though these joints cannot be radiographed)

- If the joint efficiency is capped at a lower value (e.g., 0.85), would this require the overall equipment to default to RT3, thus excluding RT1 or RT2?

- If the equipment defaults to RT3, would this require changes to the design calculations to match the radiographic category and ensure compliance?

- Weld joint efficiency applies only to components designed with the design by formulas method, particularly membranes of revolution (e.g., shells or heads).

- Other components, like air-cooled or flat heat exchangers, do not require a joint efficiency.

- For corner joints meeting the dimensional and construction requirements of UW-13(2), the joint is considered structurally adequate without needing a weld efficiency factor.

Moreover, a joint efficiency lower than the effective control could be dangerous and impact the integrity of the design. Therefore, I would like to clarify if such an approach can be accepted or if it will require further adjustments.

Additionally, I referred to the following ASME Interpretations for further clarification:

- Interpretation VIII-80-117: There are no criteria in Section VIII - Division 1 for establishing joint efficiencies for corner joint attachments; only the C and ZC factors are required to determine the required thickness of the flat plate in UG-34. The NDE requirement is specified by the provisions outlined in UG-93(d)(3) and UW-13(e), and the requirements for fillet welds as given in UW-36. Moreover, f full radiographic examinations or equivalent of the longitudinal shell joints in a vessel are to be undertaken for whatever reasons, are corner joints according to Fig. UW-13.2 still allowable or must one of the constructions allowing full radiography as per Fig. UW-13.2 be adopted? Reply: Corner joints would be allowed.

- Interpretation VIII-1-04-46: Question (1): Is it required by the rules of Section VIII, Division 1 for welded joints as per Fig. UW-13.2, sketches (m) and need to be examined by full radiography or spot radiography when the vessel in which these corner joints are included is subject to the full radiography requirements of UW-11?

Reply (1): No. - Interpretation VIII-1-89-227: Assuming no radiographic examination is required by the Code, would any radiographic examination of this corner joint affect the joint efficiency used in calculating the required thickness for the seamless shell under internal pressure? Reply (1): No.

Question (2): With no radiography of this corner joint, would the joint efficiency of the seamless shell used in calculatio ns be E = 1? Reply (2): Yes.

Question (3): Would the requirements of UW-11(a)(5)(b) ever need to be met for the corner joint described above? Reply (3): No.

Thank you for your guidance!

Last edited: