Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Datum on hole pattern

- Thread starter nmine

- Start date

- Status

- Not open for further replies.

- Thread starter

- #3

Hi 3D Dave,

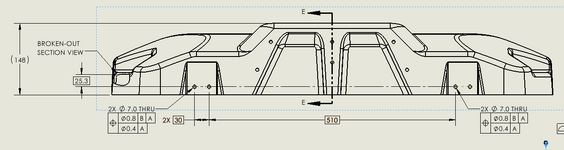

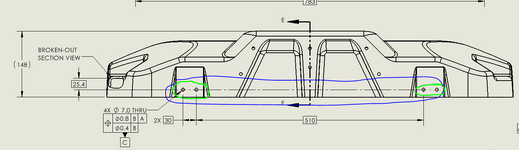

Yes I have taken a course a while back but I am definitely not an expert. I do not have the standard handy though. I'm perplexed at how I can use the four hole pattern as datum C but control the position of the green holes tighter than the position of the group ( a pattern within a pattern). If I use a composition position like in the picture below it would hold the position of all holes to 0.4 instead of what I want - 0.4 between the green holes and 0.8 between the two groups of green holes. (note: I had the wrong datum in the lower FCF)

Yes I have taken a course a while back but I am definitely not an expert. I do not have the standard handy though. I'm perplexed at how I can use the four hole pattern as datum C but control the position of the green holes tighter than the position of the group ( a pattern within a pattern). If I use a composition position like in the picture below it would hold the position of all holes to 0.4 instead of what I want - 0.4 between the green holes and 0.8 between the two groups of green holes. (note: I had the wrong datum in the lower FCF)

Just use two different single segments for the two pairs of holes and one single segment for all four holes.

This could, however, make things more complicated for manufacturing and inspection; they will probably just position all the holes to a diameter of 0.4 and ignore the larger tolerance.

This could, however, make things more complicated for manufacturing and inspection; they will probably just position all the holes to a diameter of 0.4 and ignore the larger tolerance.

pmarc

Mechanical

- Sep 2, 2008

- 3,247

The proposal provided by 3DDave will work, but both single-segment FCFs of 0.4 will need to be associated with a SEP REQT note. Otherwise, the spacing between them, due to the default simultaneous requirements rule, will still be controlled within 0.4.

Of course, the datum feature C symbol should then be associated with the 0.8 FCF.

Of course, the datum feature C symbol should then be associated with the 0.8 FCF.

Burunduk

Mechanical

- May 2, 2019

- 2,577

SEP REQT doesn't require two separate set ups, it just means that the unconstrained degrees of freedom in a single set up can be used to allow variation between the two features or patterns in a way that ignores their mutual basic location/orientation. One way to think of it is the act of moving the tolerance zones overlay across the projection of the inspected part in an optical comparator without changing how the part is set up for measurement. With SEP REQT the features are not required to fall within their tolerance zones simultaneously. Note that if all degrees of freedom are constrained SEPT REQT won't do anything.

- Status

- Not open for further replies.

Similar threads

- Replies

- 21

- Views

- 22K

- Locked

- Question

- Replies

- 9

- Views

- 3K

- Question

- Replies

- 14

- Views

- 10K

- Locked

- Question

- Replies

- 7

- Views

- 847

- Replies

- 7

- Views

- 5K