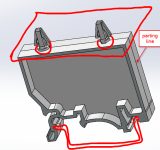

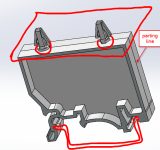

I know this question has been asked many times on this forum before, but I am still not 100% clear. What is the best strategy to datum a drafted injection molded part where no surface is really orthogonal to each other? I am attaching a picture of the part in question and I also sketched how it is mounting and getting assembled for better understanding. The lower section of the part mounts on a sheet metal part, while the top christmas tree snaps engage into a plate with 2 holes as shown. The parting line is in the center as shown. The surfaces are drafted 2 -3 degrees depending on location. So Any tips for datuming and tolerancing for this?