Pavan Kumar

Chemical

Hi All,

Further to discussion on the below thread, I developed a calculation spreadsheet to perform some sizing calculations for a Pressurized Deaerator.

www.eng-tips.com

www.eng-tips.com

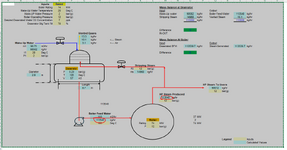

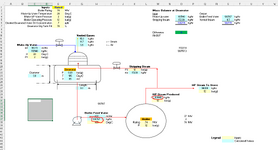

I am however facing mass balance issues at the Boiler( please see the sketch pasted below, also in the attached spreadsheet). I calculated the following from the provided Boiler Rating and Feed water temperature and the O2 Concentration in the Deaerated water.

1. Steam Generation Rate of the Boiler.

2. Make-Up Water Rate ( Considered Equal to the Boiler Steam Generation Rate as there is no condensate returned).

3. Vent Gas Flow Rate ( Air and Steam Venting Rate).

4. Deaerator Storage Tank Volume and Dimensions.

The issue I am facing is that since I considered the Make-Up water flow rate equal to the Boiler Steam Generation Rate, the input to the Boiler is not matching with the output. The difference is due to the Steam that is condensed in the Deaerator. I want to understand how a Deaerator operates in practice and how this mass balance question can be answered meaningfully. Your inputs in this regard will be very helpful to me.

Thanks and Regards,

Pavan Kumar

Further to discussion on the below thread, I developed a calculation spreadsheet to perform some sizing calculations for a Pressurized Deaerator.

Deaerator Sizing - Chemical process engineering

Hi All, Can anyone provide me the references or documents that I can use to learn about Pressurized Deaerator sizing. Any help is appreciated. Thanks and Regards, Pavan Kumar

I am however facing mass balance issues at the Boiler( please see the sketch pasted below, also in the attached spreadsheet). I calculated the following from the provided Boiler Rating and Feed water temperature and the O2 Concentration in the Deaerated water.

1. Steam Generation Rate of the Boiler.

2. Make-Up Water Rate ( Considered Equal to the Boiler Steam Generation Rate as there is no condensate returned).

3. Vent Gas Flow Rate ( Air and Steam Venting Rate).

4. Deaerator Storage Tank Volume and Dimensions.

The issue I am facing is that since I considered the Make-Up water flow rate equal to the Boiler Steam Generation Rate, the input to the Boiler is not matching with the output. The difference is due to the Steam that is condensed in the Deaerator. I want to understand how a Deaerator operates in practice and how this mass balance question can be answered meaningfully. Your inputs in this regard will be very helpful to me.

Thanks and Regards,

Pavan Kumar