Philip.screw

Structural

- Jan 4, 2024

- 8

Hello all,

I have had a number of design projects recently where I have had to design foundation to resist significant overturning forces from moment frames.

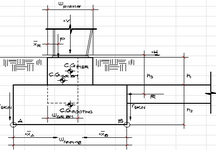

While trying to design the footings for the lateral resisting members, I was running into an issue where my software (RisaFoundation and Enercalc) would report the resultant forces are off the footing and would require footings greater than 12'x12' for it to calculate the bearing pressures. I asked my manager, who is a PE, if they had any advice to resisting the overturning. They suggested using grade / tie beams between the footings which they said would completely resist the overturning forces. Their reasoning is that the grade beam would act like a concrete beam with fixed end conditions.

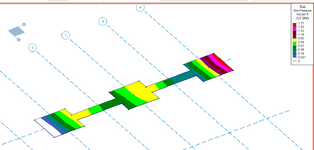

I'm having trouble understanding how the grade beam can resist all the overturning moment. I've tried modeling footings and grade beams as a matt slab, and I can see how it is providing some restraint. However, I don't think it is right to assume the grade beam completely resists overturning. From my matt slab model, I can see that the "footing" is rotating and not acting like a true fixed end condition. I believe this would make my grade beam to have a pinned end condition instead. Because of this, my footing is not acting like a true fixed condition and is allowed to rotate.

I'm curious to know if it is common to assume grade beams resist all overturning forces or if there are other design methods.

Thanks!

I have had a number of design projects recently where I have had to design foundation to resist significant overturning forces from moment frames.

While trying to design the footings for the lateral resisting members, I was running into an issue where my software (RisaFoundation and Enercalc) would report the resultant forces are off the footing and would require footings greater than 12'x12' for it to calculate the bearing pressures. I asked my manager, who is a PE, if they had any advice to resisting the overturning. They suggested using grade / tie beams between the footings which they said would completely resist the overturning forces. Their reasoning is that the grade beam would act like a concrete beam with fixed end conditions.

I'm having trouble understanding how the grade beam can resist all the overturning moment. I've tried modeling footings and grade beams as a matt slab, and I can see how it is providing some restraint. However, I don't think it is right to assume the grade beam completely resists overturning. From my matt slab model, I can see that the "footing" is rotating and not acting like a true fixed end condition. I believe this would make my grade beam to have a pinned end condition instead. Because of this, my footing is not acting like a true fixed condition and is allowed to rotate.

I'm curious to know if it is common to assume grade beams resist all overturning forces or if there are other design methods.

Thanks!