Superchief

Specifier/Regulator

I am a builder trying to understand one aspect of HVAC duct work design.

Non-engineering literature I have reviewed seems to not properly discuss the effect of pipe size on efficiency in delivering air through a HVAC system because it assumes the CFM is constant rather than the static pressure being the constant.

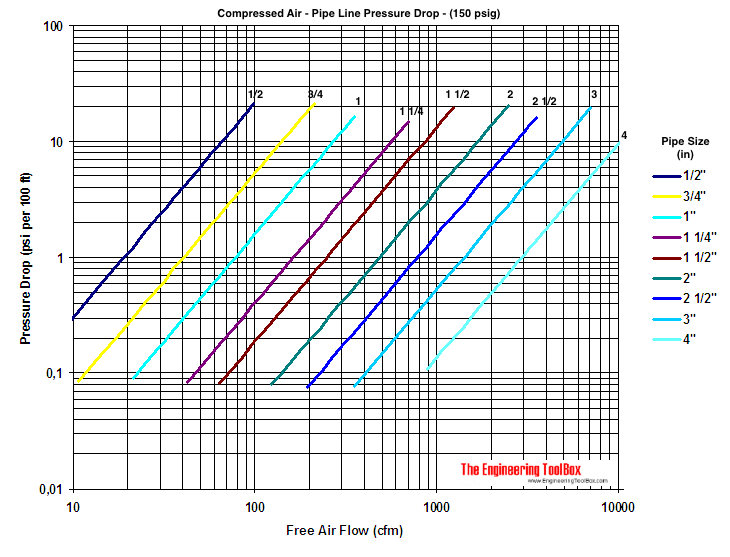

What I think I understand is that if two round pipes of different sizes carry gas (natural air) at the same static pressure the smaller pipe will deliver less CFM, but I believe the primary decrease in efficiency for the smaller pipe will come from the proportional increase in friction within the smaller pipe (e.g.: ratio of volume to wall surface area), is that correct?

If so, I would ideally like to find a formula or table that can compare the efficiency of BTUs delivered based upon pipe size ID, air temperature being carried, and distance.

A related question is whether if the distance is short (e.g.: laterals from the main trunk) does distance cease to be an important variable?

I am specifically interested in the efficiency of 2.5" ID smooth pipe versus 6", 7", and 8" smooth round duct, and if there was literature that reviewed efficiency as measured in the field that you could point me to then that would be a bonus!

Non-engineering literature I have reviewed seems to not properly discuss the effect of pipe size on efficiency in delivering air through a HVAC system because it assumes the CFM is constant rather than the static pressure being the constant.

What I think I understand is that if two round pipes of different sizes carry gas (natural air) at the same static pressure the smaller pipe will deliver less CFM, but I believe the primary decrease in efficiency for the smaller pipe will come from the proportional increase in friction within the smaller pipe (e.g.: ratio of volume to wall surface area), is that correct?

If so, I would ideally like to find a formula or table that can compare the efficiency of BTUs delivered based upon pipe size ID, air temperature being carried, and distance.

A related question is whether if the distance is short (e.g.: laterals from the main trunk) does distance cease to be an important variable?

I am specifically interested in the efficiency of 2.5" ID smooth pipe versus 6", 7", and 8" smooth round duct, and if there was literature that reviewed efficiency as measured in the field that you could point me to then that would be a bonus!