Deepak_johsh

Mechanical

Hi,

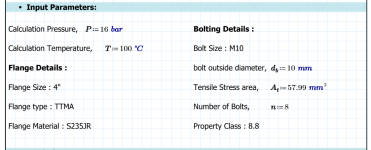

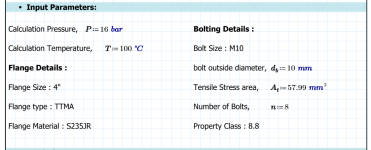

I am trying to Check if a custom flange (Dimensioned Pre-defined by TTMA) meets the requirements of EN 13480-3

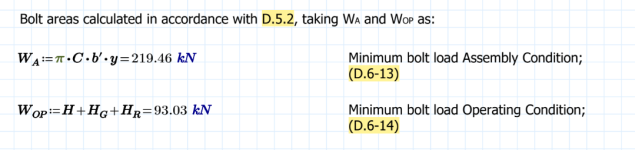

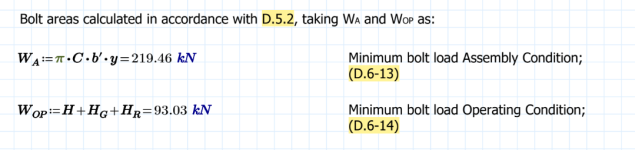

But when I do so, I find that the Bolt force is higher in Assembly condition rather than that in Operating condition.

Im looking for answers on how this can be possible?

Because, After a preload is applied to bolts of the Flange joint, fraction of any external load introduced must to taken up by the bolt.

so this must lead to bolt load in operating condition higher than that of Assembly condition.

but with the calculation as per EN 13480-3 this isnt the case.

Could anyone guide me in the right direction please?

Parameters used are as follows:

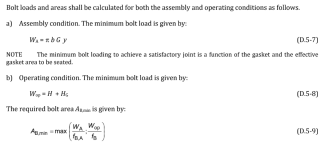

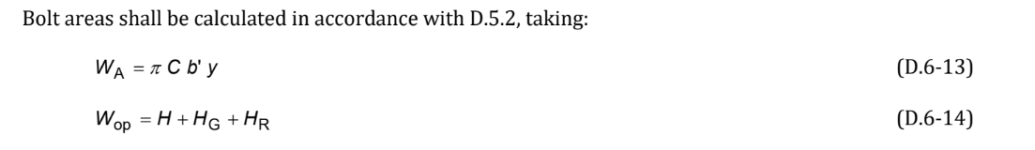

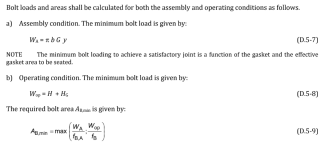

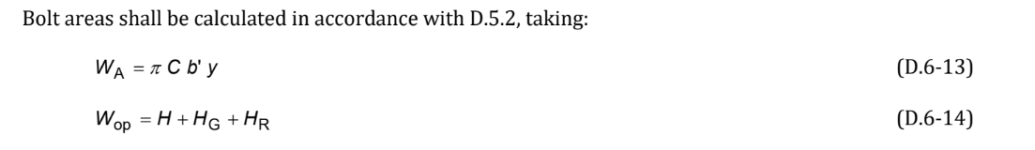

b = Effective assembly width

G = Diameter of gasket load reaction

y = minimum gasket seating pressure

H = Total Hydrostatic end force

HG = Compression load on gasket to ensure tight joint

HR = Balancing reaction force outside bolt circle in

opposition to moments due to loads inside bolt

circle

I am trying to Check if a custom flange (Dimensioned Pre-defined by TTMA) meets the requirements of EN 13480-3

But when I do so, I find that the Bolt force is higher in Assembly condition rather than that in Operating condition.

Im looking for answers on how this can be possible?

Because, After a preload is applied to bolts of the Flange joint, fraction of any external load introduced must to taken up by the bolt.

so this must lead to bolt load in operating condition higher than that of Assembly condition.

but with the calculation as per EN 13480-3 this isnt the case.

Could anyone guide me in the right direction please?

Parameters used are as follows:

b = Effective assembly width

G = Diameter of gasket load reaction

y = minimum gasket seating pressure

H = Total Hydrostatic end force

HG = Compression load on gasket to ensure tight joint

HR = Balancing reaction force outside bolt circle in

opposition to moments due to loads inside bolt

circle