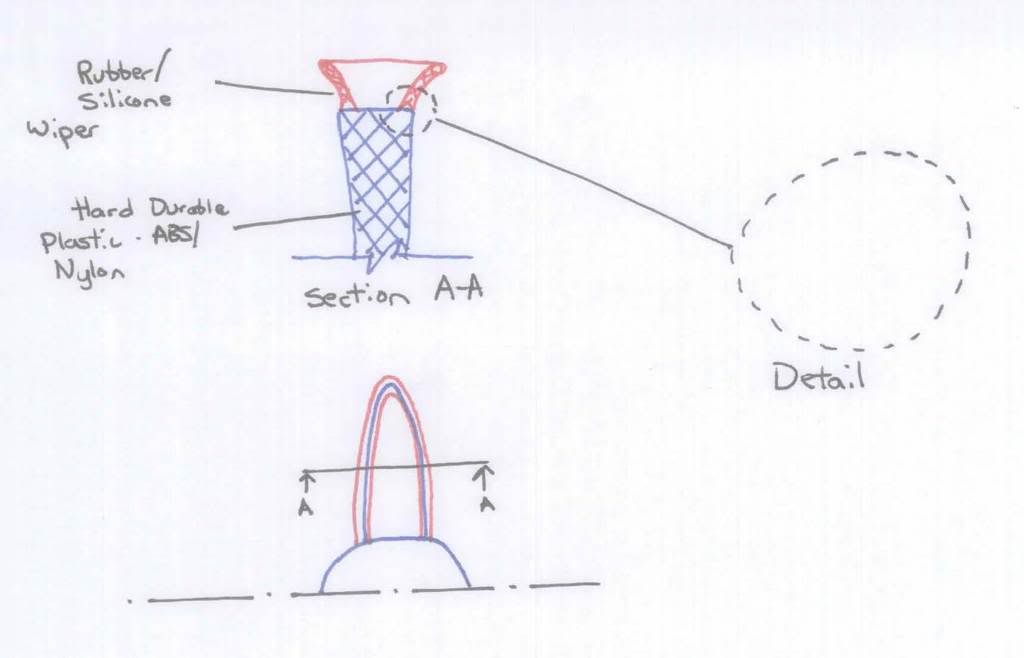

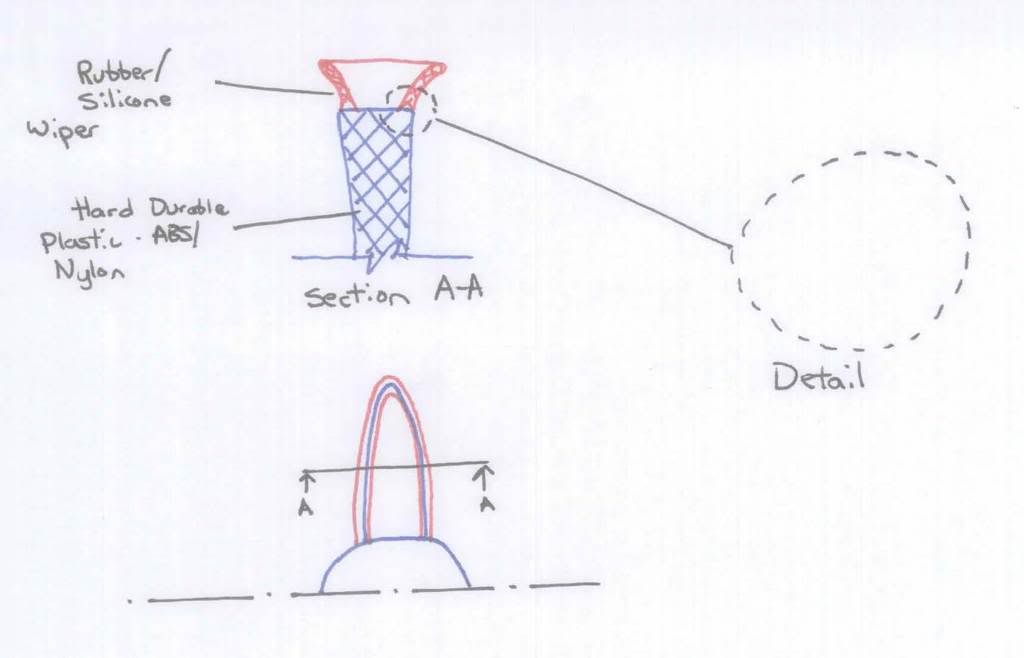

I am considering a two-shot mold and I am curious about the feasibility of this design. The profile of the 2nd shot, the wiper, can change for manufacturability. Also, I am curious about how to detail the interface of the two materials...some kind of interlocking geometry to increase bonding? The height of the softer material is appx .1" inch.

Thanks

Thanks